Just leave it out for the bin men, I'm sure they'll take itI am ready to chuck this pin out now!

Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spooky - Rick and Morty Pinball

- Thread starter Kaufmanised

- Start date

I wish I had this problem.... mine is it won’t update and has wiped the game code.Do other Spooky pins suffer from this problem?

15 different thumb drives, all formatted, from 8 -120GB and usb 3.0. Even downloaded

files via different browsers. Spooky advised changing the mobo battery which I have done but

still no luck... “Update required”

The March update worked first time...

Spooky are talking about me sending the mobo/SSD back to them “to see what is going on..”

Chris, I love it - just frustrated that the flippers die so quickly.If you are not happy with it sell it you will probably get close to your money back

I tried different settings this aft. They last a bit lomger but suffering knockdowns. Managed 3 full games, but boy those coils are getting hot. the bottom right flipper has a nice toasty wrapper now.

Spooky asked me to check EOS were working in switch tests, they are. It was the first thing I checked and adjusted ages ago, and I've checked it several times since, including today. 7

I've owned TNA and own Alice Cooper and have never had these flipper issues with either. I'm not sure if RnM flipper hardware/software is different.Do other Spooky pins suffer from this problem?

How widespread is this issue on RnM, wouldn't all owners have the same issue? I dropped out of the RnM Pinside thread a while ago so haven't kept up to date with it, but I don't recall it being anywhere near as bad as Alan in experiencing.

Chris, I love it - just frustrated that the flippers die so quickly.

I tried different settings this aft. They last a bit lomger but suffering knockdowns. Managed 3 full games, but boy those coils are getting hot. the bottom right flipper has a nice toasty wrapper now.

Spooky asked me to check EOS were working in switch tests, they are. It was the first thing I checked and adjusted ages ago, and I've checked it several times since, including today. 7

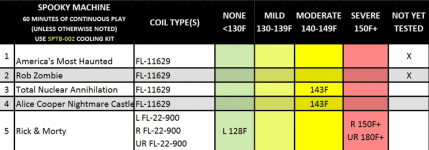

I have the flipper cooling kit I linked to earlier coming thanks to @Neil McRae, will update when it arrives and I've had a chance to install it. The Pin Monk website does give this graph re flipper temps after an hour of play which indicates that it may well be necessary:

What a shame, flippers not functioning on a pinball is kinda like the steering wheel not working on a car.

You'd think the number of years Pinball machines have had flippers they'd pretty much nailed the design down by now.What a shame, flippers not functioning on a pinball is kinda like the steering wheel not working on a car.

You'd think the number of years Pinball machines have had flippers they'd pretty much nailed the design down by now.

They have! But it's cheaper to not do it properly

yes R&M has EOS switches on the two main flippersI did not think this had NOS switches on it @AlanJ

and they are spot on adjustment wise.

Look at my right flipper coil. it’s toasting already

the lovely pink wrapper is discoloured. the coil gets sooo hot. it’s only a matter of time that the inner and sleeve will deform.

When we were developing and designing Thunderbirds we had all sorts of issues driving the flippers, mostly with coils melting.

In the end, I gave up trying to get timing right driving them from the main processor - I don't care what you do with software you will never, let me repeat NEVER get the timing so that the flippers actuate at the exact same time EVEY time and for the same duration. It simply isn't possible even using interrupts etc in the software. It's just the way this stuff works.

After spending months trying we gave up and ended up using a small PCB dedicated to each flipper and it controls ONLY that one flipper and its dual wound coil.

I'm pleased to say we haven't had a single flipper problem since doing this.

Testing the Porsche machines over this last week, we played one machine for over two hours straight (OK - I admit beers were being consumed at the time) and after that time there was no noticable differece in game play. I didn't specifically check the flipper coil temperature but the flippers were of no concern during game play so I have to assume they were fine or it would have drawn our attention.

Modulating single winding flipper coils with PWM is a recipe for certain disaster IMO. It just isn't a smart way of doing things there are just too many variables. Some ways of doing things are very suitable for the job, this is not one of them.

I'm not trying to denigrate what others are doing but I can speak from first hand and hard won knowledge.

Williams got it right with the dual winding coils, again this is all just IMO.

In the end, I gave up trying to get timing right driving them from the main processor - I don't care what you do with software you will never, let me repeat NEVER get the timing so that the flippers actuate at the exact same time EVEY time and for the same duration. It simply isn't possible even using interrupts etc in the software. It's just the way this stuff works.

After spending months trying we gave up and ended up using a small PCB dedicated to each flipper and it controls ONLY that one flipper and its dual wound coil.

I'm pleased to say we haven't had a single flipper problem since doing this.

Testing the Porsche machines over this last week, we played one machine for over two hours straight (OK - I admit beers were being consumed at the time) and after that time there was no noticable differece in game play. I didn't specifically check the flipper coil temperature but the flippers were of no concern during game play so I have to assume they were fine or it would have drawn our attention.

Modulating single winding flipper coils with PWM is a recipe for certain disaster IMO. It just isn't a smart way of doing things there are just too many variables. Some ways of doing things are very suitable for the job, this is not one of them.

I'm not trying to denigrate what others are doing but I can speak from first hand and hard won knowledge.

Williams got it right with the dual winding coils, again this is all just IMO.

D

Deleted member 2463

Agree - This is what stern does also - flippers operate independently of the CPU board.

D

Deleted member 2463

what are you talking about Willis!?Out of the new pinball manufactures. JJP are the only ones to replicate the Bally/Williams flipper feel. Even Stern to a degree with their new board set is not as good as say SAM..

JJP flippers are the spongiest ****tiest flippers in the galaxy and everyone knows that!!!

I can’t tell any difference between spike and Sam flipper wise.

Agree - This is what stern does also - flippers operate independently of the CPU board.

After spending months trying we gave up and ended up using a small PCB dedicated to each flipper and it controls ONLY that one flipper and its dual wound coil.

On these spooky games the system is split up in to the proc board and the python game code basically and is known as a pyproc based system. The proc board is the the lower 'firmware' level and controls all the actual hardware coils/lamps/switches etc. The python layer just runs the game code, graphics, sounds etc on a separate computer and is the higher layer.

Think i mentioned this before but a pyproc system has a thing called 'hardware rules' and it is here where flipper control is defined. It also handles slingshots and pop bumpers. This means that once setup the lower layer controls all the devices from switch inputs directly and doesnt need the higher layer to tell it when to operate. This is basically a modern way to do 'special coils' from the early williams days when processors were not fast enough to handle these devices and hardware only was needed. The principle still applies today amazingly.

I use this same approach on my controller boards and it all works lovely, so this area isn't something that is a problem or different to other system in my view.

The thing i dont understand its how you can have had a problem with a parallel dual wound coil and decided pwm coils were better?? Parallel dual wound coils with a hold winding were designed specifically to be able to be on all day and not burn up/fade. This is what makes zero sense to me, unless it really is just about saving pennies. I'm happy to be educated if there is a sensible explanation to this.... Anyone???

Maybe the difference in voltage being dropped to 48 from 70 has had an impact on dual wound coils power, so a revision of the wire turns and thickness is needed? (Just thinking out loud)

Plus that board is FPGA based, right? In which case, the whole software discussion doesn't even matter, as they can get whatever signal they need out of the fabric.The proc board is the the lower 'firmware' level and controls all the actual hardware coils/lamps/switches etc.

Careful - Stern does driver the flippers from software running on a CPU (unlike wms or proc which use a FPGA). Just it's the LPC1313 on the node board, not the main i.MX6 in the backbox. It is possible to get cycle-accurate outputs from software in a MCU - there are constraints however, and it's quite tricky to get it right (you often have to get creative with the peripherals). Agree it's not feasible to do so on the main CPU which is also running the game/display/etc.Agree - This is what stern does also - flippers operate independently of the CPU board.

yesPlus that board is FPGA based, right?

Something that probably needs to be thrown into the mix here was mentioned by myPinballs. Newer Sterns/Spooky etc have done away with power transformers/linear power supplies and now use switching supplies at 48V instead of the WMS style supplies running at (nominally) 70V DC.

There are a few reasons for this, the first being DRASTICALLY reduced manufacturing cost. A suitable, ready made, 48V switching supply can be bought at manufacturers level for around $30 in quantity. A WMS style transformer with associated rectifier and regulation setup (that Homepin uses) costs around $200++ at manufacturer level for quantities and is a lot more work to assemble. It is also far more reliable longer term than any switching supply - time will prove me right on this but we already know that WMS and even early Bally power transformers and supplies give very little trouble in the big scheme of things. The switching supplies used in ALL these other brands are NOT repairable - you throw it away and buy a new one for $150 (at retail).

A secondary reason (that Homepin is dealing with right now) is for electrical approvals and CE testing. 48V is BELOW 50V and 50V is the voltage that regulating authorities in most countries have chosen as being classed as "low voltage" and therefore requires far less compliance when testing a finished product. This makes for very reduced compliance testing issues and costs. Yes, the switching supply increases problems with EMI and RFI but usually most reputable manufacturers of these switching supplies have already done the hard yards with this part of the testing and supply 'ready to go' testing data.

I suspect these are the two main reasons other manufacturers have moved to these supplies. I won't do that as, in my experience, things like flippers simply don't work as well at 48V - sound familiar? Remember the flippers on early Bally and Williams machines, not as good as WMS era ones - right? Change BACK to 48V and what we see is some manufacturers scrambling to ressurect older ways of driving flippers that were tried and abandoned years ago, such as PWM - FAIL!!!

The answer here, if we want to keep the snappy and powerful flippers that we have become accustomed to, is to abandon this 48V fetish and realise that the WMS way of doing this was actually developed and honed to perfection over many years and generations of machines.

I know there will be those who disagree with me here and that's fine. If you are to comment against my thoughts here please do so with some evidence not just "but XXX flippers are OK and they use 48V" - not good enough, proof please.

FOOTNOTE: I am not claiming to be an expert electronics engineer, I am simply making comments on how I see and do things - other engineers have their opinions and ways of doing things that are equally as valid as mine. I admit to being a lot more "old school" about how I design things than many others. I am also a firm believer in "if it 'aint broke - don't fix it" and I think we are seeing far too much of this with newer machine developments.

There are a few reasons for this, the first being DRASTICALLY reduced manufacturing cost. A suitable, ready made, 48V switching supply can be bought at manufacturers level for around $30 in quantity. A WMS style transformer with associated rectifier and regulation setup (that Homepin uses) costs around $200++ at manufacturer level for quantities and is a lot more work to assemble. It is also far more reliable longer term than any switching supply - time will prove me right on this but we already know that WMS and even early Bally power transformers and supplies give very little trouble in the big scheme of things. The switching supplies used in ALL these other brands are NOT repairable - you throw it away and buy a new one for $150 (at retail).

A secondary reason (that Homepin is dealing with right now) is for electrical approvals and CE testing. 48V is BELOW 50V and 50V is the voltage that regulating authorities in most countries have chosen as being classed as "low voltage" and therefore requires far less compliance when testing a finished product. This makes for very reduced compliance testing issues and costs. Yes, the switching supply increases problems with EMI and RFI but usually most reputable manufacturers of these switching supplies have already done the hard yards with this part of the testing and supply 'ready to go' testing data.

I suspect these are the two main reasons other manufacturers have moved to these supplies. I won't do that as, in my experience, things like flippers simply don't work as well at 48V - sound familiar? Remember the flippers on early Bally and Williams machines, not as good as WMS era ones - right? Change BACK to 48V and what we see is some manufacturers scrambling to ressurect older ways of driving flippers that were tried and abandoned years ago, such as PWM - FAIL!!!

The answer here, if we want to keep the snappy and powerful flippers that we have become accustomed to, is to abandon this 48V fetish and realise that the WMS way of doing this was actually developed and honed to perfection over many years and generations of machines.

I know there will be those who disagree with me here and that's fine. If you are to comment against my thoughts here please do so with some evidence not just "but XXX flippers are OK and they use 48V" - not good enough, proof please.

FOOTNOTE: I am not claiming to be an expert electronics engineer, I am simply making comments on how I see and do things - other engineers have their opinions and ways of doing things that are equally as valid as mine. I admit to being a lot more "old school" about how I design things than many others. I am also a firm believer in "if it 'aint broke - don't fix it" and I think we are seeing far too much of this with newer machine developments.

Last edited:

No response from Spooky to me with any sort of acknowledgemeent of my issue and I have asked the support guy to escalate my problem. So far. I can just hear the tunbleweed...........

Some great info here. I wasn’t sure why but have noticed slight flipper fade on pins with the switchable 48v supplies when certain heavy load events are used. Where as the systems that use the WMS transformer 70v styles don’t seem to care what’s thrown at it and copes well. Did think the change was driven by cost, those heavy duty transformers can’t be cheap!

Last edited:

Some background reading

Compy on homebrew setups and how 48v is "more than enough for flippers"

Scott Danesi on hooking up flippers to 48v switching

MPF documentation on how 70v transformers are "generally not recommended for new games"

Different opinions on this for sure but thats a lot of knowledgable people using 48v as their solenoid power source. There's been loads of games produced using proc and FAST controllers (TBL, BOP2.0, CCC, all the spooky games, plus the homebrew stuff) and I would have thought if 48v was that massive an issue it would have been abandoned by now.

Compy on homebrew setups and how 48v is "more than enough for flippers"

Scott Danesi on hooking up flippers to 48v switching

MPF documentation on how 70v transformers are "generally not recommended for new games"

Different opinions on this for sure but thats a lot of knowledgable people using 48v as their solenoid power source. There's been loads of games produced using proc and FAST controllers (TBL, BOP2.0, CCC, all the spooky games, plus the homebrew stuff) and I would have thought if 48v was that massive an issue it would have been abandoned by now.

D

Deleted member 2463

Plus that board is FPGA based, right? In which case, the whole software discussion doesn't even matter, as they can get whatever signal they need out of the fabric.

Careful - Stern does driver the flippers from software running on a CPU (unlike wms or proc which use a FPGA). Just it's the LPC1313 on the node board, not the main i.MX6 in the backbox. It is possible to get cycle-accurate outputs from software in a MCU - there are constraints however, and it's quite tricky to get it right (you often have to get creative with the peripherals). Agree it's not feasible to do so on the main CPU which is also running the game/display/etc.

I think that’s what I said

FPGA to control a flipper mech seems overkill to me now when a microcontroller can do it easily and significantly cheaper and is probably easier to program.

Back in the WMS days they didn’t have such a capability and in many cases they were designing the semi-conductors also some of them and their VLSI and ASIC development was state of the art.

You aren’t going to differentiate game-wise on what controller you use for flippers as long as the flippers are snappy and responsive. You can short yourself in the foot though which is what Alan is seeing.

Sent from my iPhone using Tapatalk Pro

D

Deleted member 2463

Actually UL certification has dropped low voltage to under 40V thus stern has put back in a lot of the things that are needed like coin door power interruption and additional protection in some cabling and shielding.

Stern’s 48V flippers are fine - between Stern and SAM the latter driven by the transformer setup and I can’t tell the difference maybe other can chime in here - I’ve also played a TWD that was a spike design and a TWD that is the released Sam design and couldn’t tell the difference although not a lot of games on it.

JJP uses the old transformer system and they have the worse flippers in the business!

Regarding switching power supplies I’m not sure you’ll be proven to be right - there are millions of switching PSU’s that drive the Internet and servers all over the world and the MTBF on them is very substantial.

Sent from my iPhone using Tapatalk Pro

Stern’s 48V flippers are fine - between Stern and SAM the latter driven by the transformer setup and I can’t tell the difference maybe other can chime in here - I’ve also played a TWD that was a spike design and a TWD that is the released Sam design and couldn’t tell the difference although not a lot of games on it.

JJP uses the old transformer system and they have the worse flippers in the business!

Regarding switching power supplies I’m not sure you’ll be proven to be right - there are millions of switching PSU’s that drive the Internet and servers all over the world and the MTBF on them is very substantial.

Sent from my iPhone using Tapatalk Pro

@Neil McRae - Did you end up with a R&M?

Ended up at my place

Nice, how are you liking it? I've still only played two games on mine as it's still at my mate's place - his third kid was born this past week so will probably be a few more weeks before I can move it here!

@Neil McRae, why did you decide to pass on it in the end?

D

Deleted member 2463

Too many games! And LZ is epic!

Sent from my iPhone using Tapatalk Pro

Sent from my iPhone using Tapatalk Pro

If all of these "knowledgeable people" are getting it so right using 48V then why are we even having this discussion? Obviously they are NOT getting it right using 48V and worse, pulsed, single winding coils - yuk!Some background reading

Compy on homebrew setups and how 48v is "more than enough for flippers"

Scott Danesi on hooking up flippers to 48v switching

MPF documentation on how 70v transformers are "generally not recommended for new games"

Different opinions on this for sure but thats a lot of knowledgable people using 48v as their solenoid power source. There's been loads of games produced using proc and FAST controllers (TBL, BOP2.0, CCC, all the spooky games, plus the homebrew stuff) and I would have thought if 48v was that massive an issue it would have been abandoned by now.

If all of these "knowledgeable people" are getting it so right using 48V then why are we even having this discussion? Obviously they are NOT getting it right using 48V and worse, pulsed, single winding coils - yuk!

Aren't we conflating issues? Not being able to drive single wound coils consistently with pwm doesn't mean that changing 48v to 70v will fix the problem.

We have in R&M a game that uses single wound coils and 48v to drive them, and a flipper problem. Likewise we have numerous other games that use double wound coils and 48v and have no problem.

Doesn't it seem more likely the issue is the coils?

I'm really not going to buy in to what other manufacturers are doing. That is their choice and their business.Aren't we conflating issues? Not being able to drive single wound coils consistently with pwm doesn't mean that changing 48v to 70v will fix the problem.

We have in R&M a game that uses single wound coils and 48v to drive them, and a flipper problem. Likewise we have numerous other games that use double wound coils and 48v and have no problem.

Doesn't it seem more likely the issue is the coils?

What I do know and can comment on knowledgeably is the time, effort and money WE spent on flippers when we initially tried running them from the main processor. The same as pop bumpers, slings etc (which we still run from the main processor because they are nowhere near as critical as the flippers).

I do know with certainly that it is VERY difficult to get reliable, repeatable performance using PWM to drive flipper coils, particularly when it involves hold - not so much the actual 'pull' part of the operation. Similarly, running dual wound coils (similar to WMS) at 48 volts presents a bunch of different issues that we didn't fully solve and so we abandoned that idea as well.

In the end, after spending a ton of time and money chasing the "holy grail" of flipper operation and attempting to define what the "best" method of controlling them was, it was our decision to stay firmly with tried and proven dual wound coils running at 70V and controlled by their own independent circuit. Our flipper operation, I'm pleased to finally say, has zero delay, lag, or any performance issues. Our flippers are very snappy, don't overheat or fade with use and are more than powerful enough to fire a ball right to the top of several test machines we have here in the factory and don't present ANY of the problems such as overheating, buzzing, fading as is being mentioned in this thread.

All of our efforts stem from our first prototypes displayed at Pinfest in Australia many years ago where we had no end of flipper coil problems and we swore to get to the bottom of the issues once and for all. I'm pleased with our direction but I won't claim for a second that our way of doing this is the ONLY way or even the BEST way - but it works for us and it's likely the way we will continue to build machines.

PS: a coil is just a spool of wire - the issues being experienced and mentioned in this thread have almost nothing to do with the actual coil and everything to do with HOW the coils are controlled.