July 2014

SAUCER KICKER #1 REBUILD

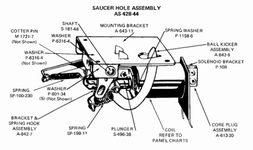

Not too tricky putting this back together other than faffing around with the brass spacer washers. Here's all the required parts to build as AS-428-44:

E-clip on one end of the shaft. Slide it in from the side and through the plunger bracket, then add 3 brass spacer washers:

Next, line up the holes in the kicker arm and push the shaft through a bit more, then add 2 more brass spacing washers:

Overview of the shaft arrangement just before pushing it out the other side of the base-plate and fixing with another E-clip. A third E-clip fits mid-shaft to keep the kicker arm and plunger bracket shifted to one side (top in this photo):

Re-fit the springs. The cotter pin through the rolled pin at the end of the plunger serves no other purpose that to provide an anchor point for the return spring:

Job done! Two more to go...

SAUCER KICKER #1 REBUILD

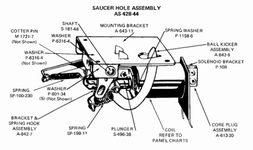

Not too tricky putting this back together other than faffing around with the brass spacer washers. Here's all the required parts to build as AS-428-44:

E-clip on one end of the shaft. Slide it in from the side and through the plunger bracket, then add 3 brass spacer washers:

Next, line up the holes in the kicker arm and push the shaft through a bit more, then add 2 more brass spacing washers:

Overview of the shaft arrangement just before pushing it out the other side of the base-plate and fixing with another E-clip. A third E-clip fits mid-shaft to keep the kicker arm and plunger bracket shifted to one side (top in this photo):

Re-fit the springs. The cotter pin through the rolled pin at the end of the plunger serves no other purpose that to provide an anchor point for the return spring:

Job done! Two more to go...