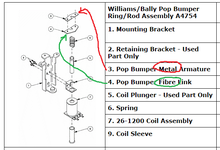

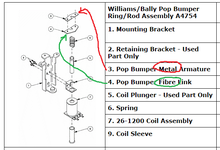

Kev, just re-reading and enjoying this log. I've recently serviced my DE pops and notice you've fitted your yolks the other way around to me. My understanding is that you want the coil plunger to pull down against the metal yolk and then recoil against the fibre as the coil de-energises. As the fibre one is slightly wider I pointed this away from the bracket too. I think this is correct per the schematic below. A minor point but you've done such an awesome job on this machine.

Attachments

Last edited: