I've also noticed that the music isn't playing so need to look into that if you have any ideas?

There is likely a game setting using the dip switches for music level.

I've also noticed that the music isn't playing so need to look into that if you have any ideas?

Tell me about it....even after you've got it all working it'll keep going wrong and require constant maintenance!

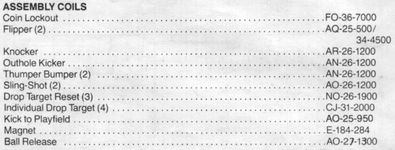

The coil has no-26-1000

That's the one it's all burnt out so hard to see the numbersThe coils are listed on page 20 of the manual - are you sure it's not NO-26-1900? That's the big chunky one that resets the target bank. 26 is wire gauge, 1900 is number of turns btw.

That worked thanks, it's so much better with soundThe options for background sounds are done in the self test options using the red button inside the door. I think from memory it is option 18 and set to number 3 using the start button (1-3)... it defaults to number 1 after a power reset.

Tell me about it....

Thanks for that @astyy was correct, it was hard to read because it was burnt out. I've got a new 1 ordered and some new rubbers.As @astyy said the coil numbers tell you the gauge (wire thickness) and number of turns, so NO-26-1000 is 1,000 turns of 26 gauge. I don't see a 26-1000 listed in the manual?

View attachment 50512

The 2-letter prefix is a code that indicates the positions of the coil lugs. Often you can use coils with different lug codes with the same gauge-winding code as long as the position of the lugs doesn't get in the way when installed.

AL = Lugs left and middle

AE = Lugs left and right

AR = Lugs right and middle

Other codes will be for double wound coils such as those for flippers (AQ) or where the bobbin includes 3 lugs for extra wiring on a single coil. Also some coils have the lugs at right angles to normal or at either end, but I'll be buggered if I can find a reliable source of information as to all the different variations!

The code C-815-1 is the Bally part number for the bobbin that makes up the core of several different coils when wound:

View attachment 50513

I've found the coil I've removed it for now untill the new one comes.Nice one @Blake7 it's rewarding getting it to a playable albeit restricted state for the first game.

Don't forget to check on the solendoid pcb the driver components for that locked coil, the t/shooting procedure is described here;

http://techniek.flipperwinkel.nl/ballyss/rep/index3.htm#driver

So apart from the drop targets not resetting all seems ok and you got sound and echo?

Not bad going.

Get the old MPU working when you have time as it is a life lesson in pinball and I reckon you could sell it for a few quid or keep it as a donor for your next project

I was going to ask the playfield is worn to the wood in a few spots. Am I best trying to get these touched up or leave them be. If I touch it up or not what would I be best to use to seal it for protection?If it was me...As long as the playfield looks clean and sound and the balls are clean, I would give them a wax and play for a few days to get a feel for the machine.

I was going to ask the playfield is worn to the wood in a few spots. Am I best trying to get these touched up or leave them be. If I touch it up or not what would I be best to use to seal it for protection?

I've just noticed another little problem, a bunch of lights aren't working they all seem to be connected together and are mostly the ones on the edge of the playfield under the plastics. The reason I noticed is because they have flashed on once or twice. Where would be the best place to start looking to fix this?

Yeah it's got the Sia installed it's just not doing much.

What's the @myPinballs board? Is it a strait replacement for the sia?