Next job is to finally try and tackle the warped left side of the main cabinet. It has quite a bad bow inwards which was causing the playfield to scrap the side and for the Pinstadiums not to stay attached. So it needed to be addressed.

Plywood is generally warps due to exposure to moisture. If it has been exposed to too much moisture it starts to move.

Basically to straighten out plywood that has warped, you need to reintroduce moisture to the opposite side and lay it in the sun with something weighing it down.

This helps balance the overall moisture content in the wood.

Sounds simple, but it has been a real challenge to fix.

My first attempt, I sprayed the concave side of the wood with hot water and clamped a straight edge to the side. I then put it out in the sun for a couple of hours.

View attachment 180846View attachment 180845View attachment 180848View attachment 180849

Unfortunately this had minimal effect, because as soon as I released the clamps, the wood bowed straight back inwards. So on to plan B

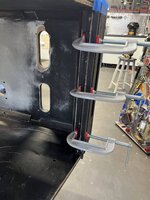

On the next attempt I sprayed the side with a lot of warm water but instead of clamping a straight edge directly to the side, I used a couple of spacers so that there was approximately 30mm between the straight edge and the side on the cabinet.

I could then over clamp it, so the plywood was actually bowing in the opposite direction. The idea being that when the clamps are released, it would bow back but just not as far.

It was abit risky doing this as there was a possibility that if I over did it, it could stay bowed in the opposite direction

.

View attachment 180844

View attachment 180843View attachment 180851

This time, instead of leaving it like this for a couple of hours, I left it clamped up for 5 days, regularly spraying hot was on the side.

When I finally removed the clamps, I could see the side slowly moving back. However my plan worked as it is now nice a straight

.

View attachment 180850