- Joined

- Jul 21, 2011

- Messages

- 11,336

- Alias

- Ive

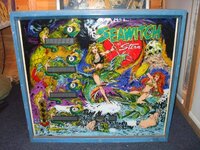

OK. Pretty rare game this in the UK, and I'm really chuffed to get my hands on one. Hopefully be of interest to people as I attempt to bring it back from the dead :thumb:

Here are just a few quick photos from setting it up yesterday to give an idea of condition.

First quick assessment ...

1. CPU board has battery leakage/corrosion. Will have to assess whether worth all the repair trouuble, or just cut to the chase and buy an all singing dancing Alltek :biggrin1:

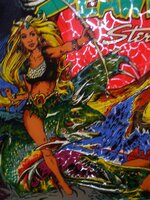

2. Backglass - It looks ok from the front BUT there is a sizeable area of paint crazing and flaking . This needs sealing asap with Krylon to prevent any further loss.

3. Playfield filthy. A few its of wear around inserts. Ball swirl etc. But overall not too bad considering this title usually got some heavy play in the wild apparently.

4. Under playfield mechs etc - small amount of corrosion but not too bad. All mechs seem to be moving freely. No obvious burned out coils.

5. Coin door really rough, very rusted. Legs cr*p too.

6. Cab not too bad.

Here are just a few quick photos from setting it up yesterday to give an idea of condition.

First quick assessment ...

1. CPU board has battery leakage/corrosion. Will have to assess whether worth all the repair trouuble, or just cut to the chase and buy an all singing dancing Alltek :biggrin1:

2. Backglass - It looks ok from the front BUT there is a sizeable area of paint crazing and flaking . This needs sealing asap with Krylon to prevent any further loss.

3. Playfield filthy. A few its of wear around inserts. Ball swirl etc. But overall not too bad considering this title usually got some heavy play in the wild apparently.

4. Under playfield mechs etc - small amount of corrosion but not too bad. All mechs seem to be moving freely. No obvious burned out coils.

5. Coin door really rough, very rusted. Legs cr*p too.

6. Cab not too bad.