Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing board connectors

- Thread starter cr5000462

- Start date

I always do it the old way and punch the wires in the new connectors. Same as original. Never had a problem.

Trifurcon molex is a better connection than IDC but tbh both are fine. It depends more on the tools you have or want to buy (crimp tool or IDC pusher)  if I didn't have either tool then I'd buy a crimper first.

if I didn't have either tool then I'd buy a crimper first.

If you’re repinning a whole connector - do it properly and go Molex.

If you’re just redoing a wire or two - use whatever is already there.

IDC was done for cost and speed reasons, not reliability. Molex is better in every way except cost and speed (on an industrial scale at least)

If you’re just redoing a wire or two - use whatever is already there.

IDC was done for cost and speed reasons, not reliability. Molex is better in every way except cost and speed (on an industrial scale at least)

Molex IDC tool (0.156") - Pinball Heaven

Excellent hand tool to replace connectors quickly and correctly. This is one of those tools that should last for years and years and still be perfect for your grandkids to use!

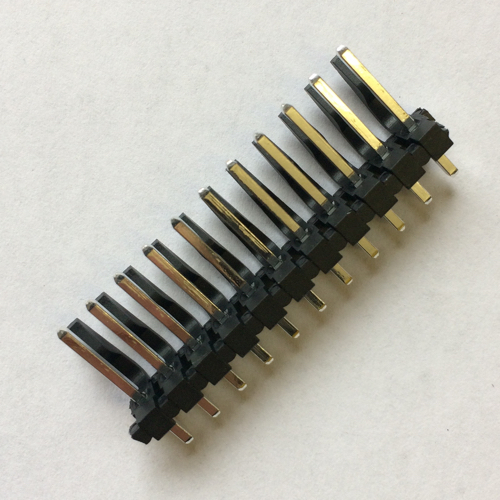

Connector, 11 pin, male 0.156 inch - Pinball Heaven

Male header connector for most pinball machines but typically GI (General Illumination) plugs that burn out.

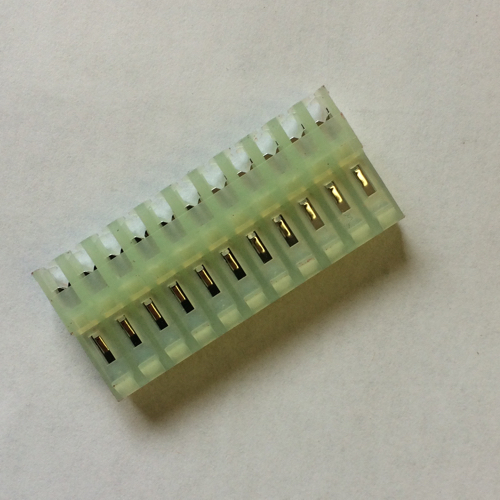

12 Pin connector, 0.156 inch, female (GI circuits J115) - Pinball Heaven

12 Pin connector, 0.156”, female (GI circuits) Look in the TOOLS section for the Molex insersion tool for use with this connector.

Oh - and a good solder sucker! Clean board with IPA to get all the crud off.

Is 0.156 a standard size for pinball machines? So in theory a whole machine could be redone with different size (in terms of number of pins) connectors

You tend to find both "large" 0.156" and "small" 0.1" (10/inch), if you go the crimp route (my preference) this tool does both (and also in-line wire to wire plugs);

HT-225D Crimp Tool for Molex Crimp Pins AWG 18-22 / 24-30 0.156" and 0.1"

HT-225D Crimp Tool for Molex Crimp Pins AWG 18-22 / 24-30

pinparts.co.uk

It is very rare you have to use the smaller ones in my experience. On most machines I have to get out the 0.156 tool....

Those crimpers of Andy's seem to be out of stock as well. I do need to get some as the 0.1 pitch for some other non pinball projects so will use crimps in keeping with the original wiring.

Ebay to the rescue.

Those crimpers of Andy's seem to be out of stock as well. I do need to get some as the 0.1 pitch for some other non pinball projects so will use crimps in keeping with the original wiring.

Ebay to the rescue.

RT19308 HT-225D Crimp Tool Ratchet 30-18Awg | eBay

Find many great new & used options and get the best deals for RT19308 HT-225D Crimp Tool Ratchet 30-18Awg at the best online prices at eBay! Free delivery for many products!

www.ebay.co.uk

Ok it's this one on Ebay

Crimping Tool Molex 0.1" 2.54mm & 0.156" 3.96mm PC Connectors Terminals HT-225D | eBay

Molex KK seriesPart No. 08-50-0032 (RS Part No. 467-598). PC HDD Power Connectors. PC Header connectors. P4 connectors. PCI-E connectors. Heavy duty professional c rimping tool for:-.

www.ebay.co.uk

- Joined

- Jul 21, 2011

- Messages

- 2,508

Due in stock this week.

Thank you,

I think I will go for the original method

So it's just buy the 0.156 tool.

Buy connectors to suit. Either 0.156 or the smaller 0.1 pitch connectors.

Punch the wires into the new connector,

Bobs your uncle it's done.

And to clarify on the new route, it's crimp the connector using the crimping tool, insert into the plastic housing, plug in and away we go.

I'm trying to keep this simple until I get the hang of it

I think I will go for the original method

So it's just buy the 0.156 tool.

Buy connectors to suit. Either 0.156 or the smaller 0.1 pitch connectors.

Punch the wires into the new connector,

Bobs your uncle it's done.

And to clarify on the new route, it's crimp the connector using the crimping tool, insert into the plastic housing, plug in and away we go.

I'm trying to keep this simple until I get the hang of it

How we looking on stock for all the different size connectors? I will be looking to buy say 6 of each in all different sizes.Due in stock this week.

You should sell a goody bag on the website

You need a polarising plug pin per connector too.

That would be for the new way?You need a polarisingplugpin per connector too.

Ideally, you use a polarising pin for both approaches (and sizes) it's what aligns the connector housing with the missing pin on the header to avoid plugging into the wrong place.That would be for the new way?

You can always take the one polarising pin out of the old connector if you use the same type.

Personally I prefer to swap like for like. IDC on pinballs and molex crimps on arcade/jukeboxes.

Personally I prefer to swap like for like. IDC on pinballs and molex crimps on arcade/jukeboxes.

YesAm I being a girl here or are the idc connectors super hard to push in, really hurt my hands doing them, often slipping and nearly stabbing myself

Might change to crimped

I’ve got an old British Telecom IDC tool from the eighties and its a piece of cake

Am I being a girl here or are the idc connectors super hard to push in, really hurt my hands doing them, often slipping and nearly stabbing myself

Might change to crimped

I’m having the same issue, it’s 18 gauge wire and just seems to thick, already written off my plastic idc tool.

Sent from my iPhone using Tapatalk

Do krone tools work on these then?? i thought the pitch would be all wrong!!I’ve got an old British Telecom IDC tool from the eighties and its a piece of cake