Some of you may remember us talking about screens for the back box text last year and I said I make them as part of my job. Well I thought some of you may find the process of actually developing the screen interesting.

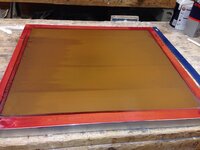

This is how they come in even tho they look clean you have to degrease them. It has to be thoroughly rinsed else the smallest residue left can ******** up the next stage. Frames can be reused indefinitely or until the silk perished. The olde emulsion is washed off using something called dissolve paste. Which has some chem in that flares my dermatitis up infact every chem I use for screens does lol so must be a few nasties in it.

The next stage is to coat it with uv sensitive emulsion. Which you use a special trough to apply. Takes about 12 hours to dry before you can use it.

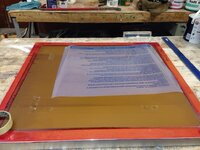

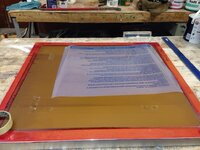

When I make them for work I'm not this OCD but with my backbox one I bought a frame the same width as a bw backbox but a little shorter. I then positioned the artwork (kindly borrowed from Daz) in exactly the right position as the original printing so that it I position the frame at the bottom corner it will print dead on in the right place. Anyway you tape the artwork back to front on the smith side (not the recessed side).

Then into the vacuum table to hold it securely

Then you flip the table so it faces a big uv light which has a special timer which I've tweaked over the years so the screens come out just right every time. Basically how it works is wherever there is artwork that blocks the uv from activating the emulsion.

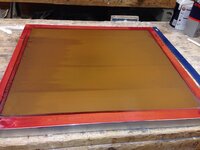

Then you take the frame out, remove the artwork and wash with warm water and all that's not been activated washes off leaving clear silk.

And dried ready to use. When we use them for marking cut work I put hinges on them and mount them on boards which are marked so you line up the piece on the board, close the board and dust with chalk then they have all their positions and stich marks.

I'm bloody sick of frames lately had to do 3 sets for cbn suits 15 frames each set and bloody huge ones got another 4 sets of them to do grr. Anyway I hope it enlightened a few of you

This is how they come in even tho they look clean you have to degrease them. It has to be thoroughly rinsed else the smallest residue left can ******** up the next stage. Frames can be reused indefinitely or until the silk perished. The olde emulsion is washed off using something called dissolve paste. Which has some chem in that flares my dermatitis up infact every chem I use for screens does lol so must be a few nasties in it.

The next stage is to coat it with uv sensitive emulsion. Which you use a special trough to apply. Takes about 12 hours to dry before you can use it.

When I make them for work I'm not this OCD but with my backbox one I bought a frame the same width as a bw backbox but a little shorter. I then positioned the artwork (kindly borrowed from Daz) in exactly the right position as the original printing so that it I position the frame at the bottom corner it will print dead on in the right place. Anyway you tape the artwork back to front on the smith side (not the recessed side).

Then into the vacuum table to hold it securely

Then you flip the table so it faces a big uv light which has a special timer which I've tweaked over the years so the screens come out just right every time. Basically how it works is wherever there is artwork that blocks the uv from activating the emulsion.

Then you take the frame out, remove the artwork and wash with warm water and all that's not been activated washes off leaving clear silk.

And dried ready to use. When we use them for marking cut work I put hinges on them and mount them on boards which are marked so you line up the piece on the board, close the board and dust with chalk then they have all their positions and stich marks.

I'm bloody sick of frames lately had to do 3 sets for cbn suits 15 frames each set and bloody huge ones got another 4 sets of them to do grr. Anyway I hope it enlightened a few of you