Iv just started playing with fusion 360 how did you add the screws?Little bit of progress.

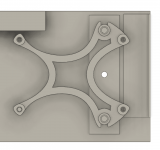

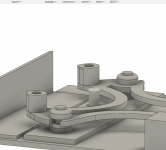

I've measured the environment in that section of the backbox and mapped it, so we can accurately see whats going on.

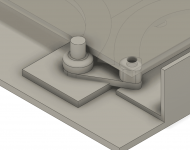

We want to use the existing bolts on right (****ty modelling on that but you get the picture)

We want the bolt for wingnut available on the left

We want this to be cuttable via a laser as well as 3d printed (so have included stand off spacer that insert separately, but can be 3d printed) I have used board height at 3mm so we can use 3mm acrylic (standard size, like protectors)

Kept design style fluid so it looks a little nicer (subjective) I'll likely take a cut out of the middle to save on 3d print time and materials.

Made better use of the space on the right (moved assembly further right). The board just fits between the bolts, but not between the nuts, so we can move it right, but need to lift it above the nuts when it sits on the frame. Done.

If the user doesnt want to use the nuts on the right to hold it down (would likely be over kill!), you could place the PCB Holder on the same bolts, on TOP of the existing nuts, then fix it down with second nuts. In this sceanrio, user can increase the height of the stand offs between backbox floor and the frame (can probably use the ones we likely all have lying around for pinballs.)

View attachment 129701

The frame sits under the nuts on the right, stand offs press through the frame on the left to support that side of the board

Rough animation to try and show it all below.

View attachment 129703

View attachment 129704

Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Afterglow 1.3 Board

- Thread starter biglouieuk

- Start date

It's not so much that the tolerance of the machine is not right enough, although it could definitely be better!Happy to give it a go here if that would help??? I should be able to get down to 0.05mm (allegedly) according to Pruslicer... Never gone down THAT fine!!

It's because I'm trying to use self tapping screws I to the pla. It snaps. Is not strong and the design is the round and round tower.

I think it either needs a snap in top or a bolt and nut..

I'll do some more designing, see what's what. It's a better placement for sure.

Fifty

Registered

Wow! I am liking the way this is headed! Nice work @biglouieuk ! Does the existing thread bolt rub on the bottom of the AG board? It looks like it would be pretty tight there.

you mean the two bolts? If so, no. The board itself fits between the two bolts! I'll physically check it tomorrow when I get the board in again..Wow! I am liking the way this is headed! Nice work @biglouieuk ! Does the existing thread bolt rub on the bottom of the AG board? It looks like it would be pretty tight there.

This has turned into quite a project! I've got hours in this! Obsession! Haha

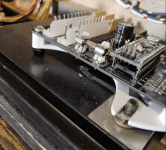

So the morning update.

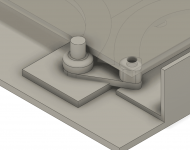

Printed a new version with much sturdier stand offs on the top of the frame. This will cause issues for the laser requirement, BUT I am sure we can cut the frame and then the stand off/washers from same material on the same job setup? Standoff, on top of frame, is deliberately 6mm in height, so that we can cut the frame (3mm thick) and 8 stand-off washers (2 sets of 4) and they can be CA glued onto the frame in stacks, or just have round ones that float. Means the laser can do a single set up from 3mm material. Speeds that up. Or can make the stand off 8mm and have the frame cut at 3mm and stand offs at stained 8mm acrylic.

I've used M4 machine screws right through to act as fixing for the board and as standoff for the base. Into 4mm holes on the frame, so it holds it all together. Needs a 20mm machine screw (mines is 16mm here) and 12mm for the right hand side ones.

The board does drop down in the middle of the existing bolts. But, if you install the board first, you won't get the bolts back on as the board is too close. So you would need to put the frame in, bolts and then board. Not ideal. I'm trying to get to a point where you don't faff around with screwdrivers in the backbox to put the board on the frame once in situ as it's all too fiddly.

In the images I've placed the frame OVER the existing bolts and nuts. I prefer this for ease of install. Again might be tricky to get a nut in there, but a flatish 1/4" nut would work if we opened up the rear 1/4" hole so we can slide into the back then pop the back nut on, before you slide it on.

Does it even need to be held down? If the bolt holes we only slightly over sized you'd get a very snug fit across two points...

Could also increase the board to frame stand off to give more room to work a nut in.

Or we could use a 1/4" e-clip to hold it down on the front. Might be nice.

So the morning update.

Printed a new version with much sturdier stand offs on the top of the frame. This will cause issues for the laser requirement, BUT I am sure we can cut the frame and then the stand off/washers from same material on the same job setup? Standoff, on top of frame, is deliberately 6mm in height, so that we can cut the frame (3mm thick) and 8 stand-off washers (2 sets of 4) and they can be CA glued onto the frame in stacks, or just have round ones that float. Means the laser can do a single set up from 3mm material. Speeds that up. Or can make the stand off 8mm and have the frame cut at 3mm and stand offs at stained 8mm acrylic.

I've used M4 machine screws right through to act as fixing for the board and as standoff for the base. Into 4mm holes on the frame, so it holds it all together. Needs a 20mm machine screw (mines is 16mm here) and 12mm for the right hand side ones.

The board does drop down in the middle of the existing bolts. But, if you install the board first, you won't get the bolts back on as the board is too close. So you would need to put the frame in, bolts and then board. Not ideal. I'm trying to get to a point where you don't faff around with screwdrivers in the backbox to put the board on the frame once in situ as it's all too fiddly.

In the images I've placed the frame OVER the existing bolts and nuts. I prefer this for ease of install. Again might be tricky to get a nut in there, but a flatish 1/4" nut would work if we opened up the rear 1/4" hole so we can slide into the back then pop the back nut on, before you slide it on.

Does it even need to be held down? If the bolt holes we only slightly over sized you'd get a very snug fit across two points...

Could also increase the board to frame stand off to give more room to work a nut in.

Or we could use a 1/4" e-clip to hold it down on the front. Might be nice.

Attachments

-

IMG_20210110_113748.jpg128.8 KB · Views: 15

IMG_20210110_113748.jpg128.8 KB · Views: 15 -

IMG_20210110_113745.jpg133.2 KB · Views: 18

IMG_20210110_113745.jpg133.2 KB · Views: 18 -

IMG_20210110_113736.jpg79.4 KB · Views: 15

IMG_20210110_113736.jpg79.4 KB · Views: 15 -

IMG_20210110_113726.jpg149.4 KB · Views: 14

IMG_20210110_113726.jpg149.4 KB · Views: 14 -

IMG_20210110_113327.jpg110.3 KB · Views: 13

IMG_20210110_113327.jpg110.3 KB · Views: 13 -

IMG_20210110_113213.jpg131.9 KB · Views: 12

IMG_20210110_113213.jpg131.9 KB · Views: 12 -

IMG_20210110_113209.jpg143.2 KB · Views: 12

IMG_20210110_113209.jpg143.2 KB · Views: 12 -

IMG_20210110_113207.jpg144.4 KB · Views: 13

IMG_20210110_113207.jpg144.4 KB · Views: 13 -

IMG_20210110_113156.jpg91.7 KB · Views: 15

IMG_20210110_113156.jpg91.7 KB · Views: 15 -

IMG_20210110_113151.jpg83.8 KB · Views: 15

IMG_20210110_113151.jpg83.8 KB · Views: 15

Last edited:

Fifty

Registered

I'm having trouble following what you have written. From the photos it is looking fantastic. The machine screws sticking out is not ideal. It looks unfinished, but I suppose you need something on the threaded end of them to secure the board to the 3D print. Perhaps a nylon lock nut?

The angle it is on in this photo also has my OCD kicking in. I would have to figure out a way to level this out. Perhaps it's just the camera playing tricks on my eye? Is there a reason why the machine screws on the right have to sit on the L bracket? Could the design be modified to slide everything to the right closer to the existing threaded bolts?

Overall I think it is a very clever and stealth design. I like the styling and using the existing threaded bolts is working. What about designing it to sit under the flange nut on those threaded bolts? This way you just remove the two flange nuts, place the 3D print over top of the threaded bolts, then use the flange nuts to secure it down? The 3D print would never move. You'd just have to make sure not to over tighten it.

Great work so far! I think you are almost there, but there are still some tweaks that would make your design even better!

The angle it is on in this photo also has my OCD kicking in. I would have to figure out a way to level this out. Perhaps it's just the camera playing tricks on my eye? Is there a reason why the machine screws on the right have to sit on the L bracket? Could the design be modified to slide everything to the right closer to the existing threaded bolts?

Overall I think it is a very clever and stealth design. I like the styling and using the existing threaded bolts is working. What about designing it to sit under the flange nut on those threaded bolts? This way you just remove the two flange nuts, place the 3D print over top of the threaded bolts, then use the flange nuts to secure it down? The 3D print would never move. You'd just have to make sure not to over tighten it.

Great work so far! I think you are almost there, but there are still some tweaks that would make your design even better!

So your eyes are not playing tricks.

It slopes to the left slightly because I dont have the screws we need.

Left Screws coming through acts as the standoff. I only had 16mm M4s, it needs 20mm M4s to level it.

The right hand M4 screws do NOT need to touch the plate, nor should they. They need to be M4 12mm. I didnt have any.

There are two ways to work to install, as you point out.

1. Bolt it down under those existing nuts.

Pro - Holds it tight

Cons - We dont need that much hold down? The board is in the way of the nuts when you want to screw them down.. So you need to install the frame, THEN the AG board and its fiddly as f*&k to get those 4 screws in. here are solutions to that. But.. Let me get a picture...

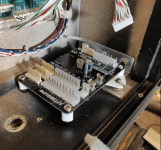

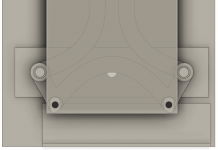

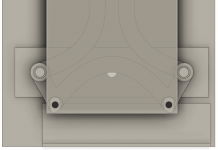

From above. You can see how the nuts overlap the board. Its fine if you secure the frame down first with nuts, then come in with the board n top (frame has 6mm stand off built in, so the board sits above the nuts, between the bolts.

From the side. If you go, frame in, nut down, then board on top with 4 screws it works. Fiddly.

It feels better to attach the board onto the frame, drop the frame over the 2 bolts with nuts and then secure with clip.

I'll do a couple more 3d printer prototypes and then laser some and send them out to you to test.

Incidentally, this is for my BOP, so Williams WPC. Do these bolts differ on differing machines?

It slopes to the left slightly because I dont have the screws we need.

Left Screws coming through acts as the standoff. I only had 16mm M4s, it needs 20mm M4s to level it.

The right hand M4 screws do NOT need to touch the plate, nor should they. They need to be M4 12mm. I didnt have any.

There are two ways to work to install, as you point out.

1. Bolt it down under those existing nuts.

Pro - Holds it tight

Cons - We dont need that much hold down? The board is in the way of the nuts when you want to screw them down.. So you need to install the frame, THEN the AG board and its fiddly as f*&k to get those 4 screws in. here are solutions to that. But.. Let me get a picture...

From above. You can see how the nuts overlap the board. Its fine if you secure the frame down first with nuts, then come in with the board n top (frame has 6mm stand off built in, so the board sits above the nuts, between the bolts.

From the side. If you go, frame in, nut down, then board on top with 4 screws it works. Fiddly.

It feels better to attach the board onto the frame, drop the frame over the 2 bolts with nuts and then secure with clip.

I'll do a couple more 3d printer prototypes and then laser some and send them out to you to test.

Incidentally, this is for my BOP, so Williams WPC. Do these bolts differ on differing machines?

Here's a thought (You have probably thought of this already). Cut out around the Nuts to keep them clear. Use 1" Self tappers to mount down the board down through the mount and into the machine.

Requirements : 4x 1" Self tappers, the 3d print and the AGGI board. Job done.

Requirements : 4x 1" Self tappers, the 3d print and the AGGI board. Job done.

Fifty

Registered

Fixed.Here's a thought (You have probably thought of this already). Cut out around the Nuts to keep them clear. Use 1" Self tappers to mount down the board down through the mount and into the machine.

Requirements : 4x 1" Self tappers, the 3d print and the AGGI board. Job done.

Requirements : 4x 1" Self tappers, the 3d print and the AG board. Job done.

This is for the AG board, not the AGGI. Just wanted to make that clear so as to not confuse people reading this.

Definitely another option there Paul, yup.

Forget the bolts, come out round the nuts as well and secure down through the 4 frame holes?

From an OCD perspective (there is some agreement that pinheads suffer a little?) we need to consider the 2mm drop between the metal plate on right (that frame now rests on) and the floor of the back box on the left. Of we laser with 3mm acrylic, it will hold that up in the air anyway!

Of we laser with 3mm acrylic, it will hold that up in the air anyway!

I like the idea of going round the nuts, I'll model a few of these ideas this evening and post. Have a few thoughts I want to try also.

I'm obsessing about not having to attach the board to the frame once in place, as I had a nightmare getting that done this morning.

I think, secure frame down using those two bolts. Have stand offs with clips that allow the board just to snap down onto them. Done.

I find modeling the snappy bit hard and 3d print will be tricky, laser won't be any good at that at all

Forget the bolts, come out round the nuts as well and secure down through the 4 frame holes?

From an OCD perspective (there is some agreement that pinheads suffer a little?) we need to consider the 2mm drop between the metal plate on right (that frame now rests on) and the floor of the back box on the left.

I like the idea of going round the nuts, I'll model a few of these ideas this evening and post. Have a few thoughts I want to try also.

I'm obsessing about not having to attach the board to the frame once in place, as I had a nightmare getting that done this morning.

I think, secure frame down using those two bolts. Have stand offs with clips that allow the board just to snap down onto them. Done.

I find modeling the snappy bit hard and 3d print will be tricky, laser won't be any good at that at all

This one goes around the nuts.

View attachment Afterglow 11 v1.mov

You can see that we have the 2.5mm metal plate height to contend with, meaning the left hand side has the frame lifted off the machine floor.

We could model so that the screws come down through and hit between the two metal plates on the right... Tricky..

View attachment Afterglow 11 v1.mov

You can see that we have the 2.5mm metal plate height to contend with, meaning the left hand side has the frame lifted off the machine floor.

We could model so that the screws come down through and hit between the two metal plates on the right... Tricky..

Fifty

Registered

Can feet be added to the left side that are 2.5mm?

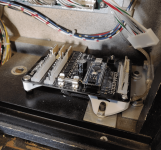

Final version is now complete and working well.

- Designed so no drilling is needed

- Designed so it can utilise existing hardware (the hinge bolts)

- Make best use of the space in confined area with minimal faff

- Solid, easily printable and relatively easy laserable (laser will require a bit of assembly)

- Board attaches to frame before installation to minimise messing about with screws in small space

- Leave original 1/4" bolts for the hinge in place and untouched

The kit has

Printed frame

2 x 1/4" flat nuts (not in images)

4 x M4 machine screws

2 x nylon black nut caps (left hand adjustable feet)

Install is as simple

1. Attach the board to the frame using M4s , screw all the way down(they screw into frame easily and hold)

2. Attach two black nuts to left hand side M4s for adjustable feet

3. Add one of the 1/4" flat nuts on the back hinge 1/4" bolt. Tighten the nut a little, but not all the way. Leave 3mm ish)

4. Slot the board round existing bolt at back, under the nut from Step 3. Tighten back nut down.

5. Slot board over front bolt, and spin down the flat 1/4" nut.

I think its worth either taping down the earth wire or cutting back to the metal support. Ensure it gets continuity to the metal bar if you do that obviously. This will avoid any shorts to the bottom of the board? Precaution.

- Designed so no drilling is needed

- Designed so it can utilise existing hardware (the hinge bolts)

- Make best use of the space in confined area with minimal faff

- Solid, easily printable and relatively easy laserable (laser will require a bit of assembly)

- Board attaches to frame before installation to minimise messing about with screws in small space

- Leave original 1/4" bolts for the hinge in place and untouched

The kit has

Printed frame

2 x 1/4" flat nuts (not in images)

4 x M4 machine screws

2 x nylon black nut caps (left hand adjustable feet)

Install is as simple

1. Attach the board to the frame using M4s , screw all the way down(they screw into frame easily and hold)

2. Attach two black nuts to left hand side M4s for adjustable feet

3. Add one of the 1/4" flat nuts on the back hinge 1/4" bolt. Tighten the nut a little, but not all the way. Leave 3mm ish)

4. Slot the board round existing bolt at back, under the nut from Step 3. Tighten back nut down.

5. Slot board over front bolt, and spin down the flat 1/4" nut.

I think its worth either taping down the earth wire or cutting back to the metal support. Ensure it gets continuity to the metal bar if you do that obviously. This will avoid any shorts to the bottom of the board? Precaution.

Attachments

Last edited:

Fifty

Registered

Mine is two bolts, this does cause an issue.

The middle bolt would be up through the board itself.

We would need to increase the stand off height quite a bit to avoid it.

ill take a look later on..

The middle bolt would be up through the board itself.

We would need to increase the stand off height quite a bit to avoid it.

ill take a look later on..

Take out the centre bolt.

+1 for thisTake out the centre bolt.

Fifty

Registered

Pass. Thanks for the suggestion.Take out the centre bolt

Take out the centre bolt.

Was gonna say that.... Is overengineered for the weight of the head anyhow

It matters not, it's designed to work both ways.

Fifty

Registered

Your 3D rendering videos are sexy as hell! Well done.

Nice that it misses the middle bolt like that already. Kudos!

Nice that it misses the middle bolt like that already. Kudos!

Little bit of luck in the middle bolt situation I think!

Printers misbehaving or I'd get some printed and out to you guys to test.

Once machine is back up, happy to make them up.

Printers misbehaving or I'd get some printed and out to you guys to test.

Once machine is back up, happy to make them up.

Little bit of luck in the middle bolt situation I think!

Printers misbehaving or I'd get some printed and out to you guys to test.

Once machine is back up, happy to make them up.

I'm busy printing out Rebar supports for some concrete work i'm doing in the garden on the weekend

f^king robots.. I dunno how they plan to take over the world, they cant even warm up some plastic and spit it out..

caponian

Registered

Sorry, I have completely missed this thread. Love the 3D printed frame!

Are you still having trouble with the configuration tool? I remember vaguely having similar issues on Windows. But I did not test much as I'm developing all on Linux.

Are you still having trouble with the configuration tool? I remember vaguely having similar issues on Windows. But I did not test much as I'm developing all on Linux.

Hey there! I havent really tried again on config. I was hoping to get new firmware on it, I have a Mac, but was trying on a Windows machine. Just couldnt get connected, I think I manged with Arduino IDE, maybe I can flash from there with new firmware?Sorry, I have completely missed this thread. Love the 3D printed frame!

Are you still having trouble with the configuration tool? I remember vaguely having similar issues on Windows. But I did not test much as I'm developing all on Linux.