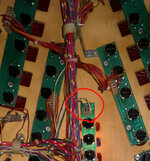

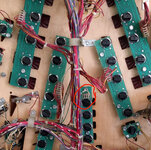

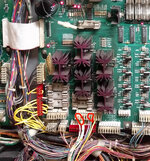

The most burnt looking pin on J115 is pin 11, which is not the Green GI circuit serving the CPU light board., so that one is not the issue. The green circuit is pin 5 and pin 10 of J115. Both of these look OK in pic but check for continuity in the circuit (using DMM in diode/continuity buzz test. Pinwiki has an excellent write up on GI operation and diagnosis including a really neat diagram of each of the 5 GI circuits. https://www.pinwiki.com/wiki/index.php?title=Williams_WPC#General_Illumination_ProblemsI am going to take the board off again at the weekend and resolder this pin on J115 (I think that's it). Will try and melt the burned solder and reflow it.

And I wouldn't just carry out random work on a board until confirming exactly what the fault is through testing and would also caution against trying to doing any board work unless you have a temperature controlled solder station, not just an iron.

Last edited: