Pic one shows a anchor point but does it have another point as well , cannot see a wall the other side .

Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stairs Solution - Winch

- Thread starter Rob zombie

- Start date

Yeah I think I may have seen every stair winch video ever recorded at this stage lol

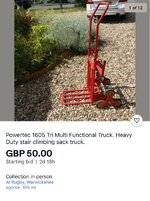

Just done a quick test with the sack truck on it’s own going up the stairs. It’s definitely going to need to go on runners or cardboard due to the geometry of the wheel spacing vs step tread depth.

Ok !

Have a look at this it will help some

I am so cool at making VTs

Have a look at this it will help some

I am so cool at making VTs

Ok !

Have a look at this it will help some

I am so cool at making VTs

Mmm that’s really interesting! I was watching a guy who had it hooked up low down and thinking “yeah that’s going to tip down the stairs”, now I understand the engineering logic. Probably could thread it through the handle to avoid tipping.

Having that way you are having the weight working with you not against you which means the brace between the the walls does not need to be massive and have less strain . Try it yourself you will see how much effort is required , less is good in my book !!

My advice - take the backbox off. 1 hours work to take off and put back on. Take this down.

Take down pinball glass

Personally I would remove the playfield - take that down.

Slide cabinet down the stairs.

BETTER STILL - simply ask for some help!

FFS - someone put a mask and gloves on and go help the man if you are local.

It shouldn't make a difference about anyones condition - the fittest man in the world would struggle getting it down alone.

The winch to me seems like an accident waiting to happen - what if something goes wrong and the pinball jams itself somewhere - it will need more than two people to sort that out as well as damage the pinball and your property.

Be safe !

Take down pinball glass

Personally I would remove the playfield - take that down.

Slide cabinet down the stairs.

BETTER STILL - simply ask for some help!

FFS - someone put a mask and gloves on and go help the man if you are local.

It shouldn't make a difference about anyones condition - the fittest man in the world would struggle getting it down alone.

The winch to me seems like an accident waiting to happen - what if something goes wrong and the pinball jams itself somewhere - it will need more than two people to sort that out as well as damage the pinball and your property.

Be safe !

It'll be fine  I've had a couple of near death moments on the stairs while being helped by one or more people. I've had pinball machines, heavy gym equipment and even a 7ft slate bed ex-pub Superleague pool table go up and down those stairs. At this stage I feel that all the helpers in the world are not going to make it risk free. It needs a proper engineering solution. And frankly I could do without the week long spinal recovery.

I've had a couple of near death moments on the stairs while being helped by one or more people. I've had pinball machines, heavy gym equipment and even a 7ft slate bed ex-pub Superleague pool table go up and down those stairs. At this stage I feel that all the helpers in the world are not going to make it risk free. It needs a proper engineering solution. And frankly I could do without the week long spinal recovery.

I agree that the winch method is the best option if done properly. The first rule of Manual Handling is avoid it wherever possible. Letting a winch do the work will be much safer than man-handling a machine up/down those stairs.

Iv put countless fruit machines / 2 pins upstairs but always had 3 people doing it and even that scared the **** out of me lol

I guess long as your not under the pin no one will die but might cause some serious damage if **** gets real

I guess long as your not under the pin no one will die but might cause some serious damage if **** gets real

Could just grease up the machine and the stairs and ride it down White Water style.

After the Theatre of Magic bobsleigh ride I had the other month, honestly a winch is the way forward.

Looking at your stairs , which don’t seem to have a steep pitch, I’d ditch the trolley( now you’ve bought it!!!) and look at banging up a basic plywood sled( one cabinet size sheet with 3x2 edges with leading edges plastic covered) as long as you affix strap to cabinet, NOT sled , should be great with the winch.

I’ve still got the cardboard box from TWD so I was thinking I could just use that as a runner. I’ve got a 4 metre 2 tonne strap coming tomorrow. Just need to source a decent bar now. Thinking maybe a barbell.

If you mean the brace bar you’d be better with some hefty angle iron to spread the load across your wall and also provide a larger friction surface to prevent movement. Think I might have a 2 m length of 5” by 5”

Blimey, that’s a flippin girder! The only thing I’m thinking is that the bar needs to be smaller in diameter than the brackets that come with the winch. Otherwise I don’t know how I would go about securing it and it could end up being the weak point in the chain. So I’m thinking a weight lifting bar capable of 250kg is ideal. I can attempt to spread the load up the wall with planks of wood.

Many years ago I was very nearly crushed to death by my old Paragon when I decided I could get it downstairs and out of my old terraced house alone. Engineering solution or not, I just wouldn't risk it dude!

For some reason I'm reminded of Rod Hull

For some reason I'm reminded of Rod Hull

Problem I see is if your load gets lodged or jammed against a step, even by a cm, coming up. Your weakest points then would be that bar, followed by the wall( which is designed to take vertical load not horizontal stress) and then your load strap( and possibly the pinball), remember loads get multiplied by distance and friction , think it’s referred to as breaking strain. Normally these winches have bolt holes in the base for surface mounting. When you think you have a plan I can come round and tap your walls and advise on weak points in design, I’ve experience of loading dead cars and commercial catering equipment .Blimey, that’s a flippin girder! The only thing I’m thinking is that the bar needs to be smaller in diameter than the brackets that come with the winch. Otherwise I don’t know how I would go about securing it and it could end up being the weak point in the chain. So I’m thinking a weight lifting bar capable of 250kg is ideal. I can attempt to spread the load up the wall with planks of wood.

I used to live in a 3rd floor flat and had 2 pinball machines! I took them apart and used a sack truck, on my own!!

If you are using a winch, you need to spread the load on that wall, maybe some wood/plywood between the bar and the wall and I think some 2x4's down on the stairs as rails and some thick cardboard under the pinball could work, castors under the pin would be better, but i am worried about the force needed to pull a machine up the stairs, it is going to be more than you think.

If you are using a winch, you need to spread the load on that wall, maybe some wood/plywood between the bar and the wall and I think some 2x4's down on the stairs as rails and some thick cardboard under the pinball could work, castors under the pin would be better, but i am worried about the force needed to pull a machine up the stairs, it is going to be more than you think.

As pick holder says, take the head off, take the playfield out, then you’ve got 3 parts which are much easier to move by hand. No dramas.

I agree it’s worth attempting to lighten the load. I don’t have a problem removing the playfield and glass etc. That should make it a lot easier to handle.

The gap between the two walls look to be 5-6 foot gap , this will mean something like 6”x2” doubled up or even 8”x2” doubled to spread the load on the walls and to stop the flexing of the timber if t machine gets court up on a step .

ps : if you want to ditch this and want some help to move your machine , I would gladly help you , i still have a few ppf3 masks left

ps : if you want to ditch this and want some help to move your machine , I would gladly help you , i still have a few ppf3 masks left

The gap between the two walls look to be 5-6 foot gap , this will mean something like 6”x2” doubled up or even 8”x2” doubled to spread the load on the walls and to stop the flexing of the timber if t machine gets court up on a step .

ps : if you want to ditch this and want some help to move your machine , I would gladly help you , i still have a few ppf3 masks left

Thanks, I appreciate the offer! I think by the time Martin gets back to me this whole coronavirus thing may be a long and distant memory.

Thanks, I appreciate the offer! I think by the time Martin gets back to me this whole coronavirus thing may be a long and distant memory.

Have you needed to try your winch solution yet?

Have you needed to try your winch solution yet?

No, luckily Martin has been in (wearing a mask) and taken them up and down. I'll probably get to try it out in a few months time when we move house.

Yeah the stairs are really beginning to put me off the whole hobby. Next house must have a decent sized ground level space for things like that.