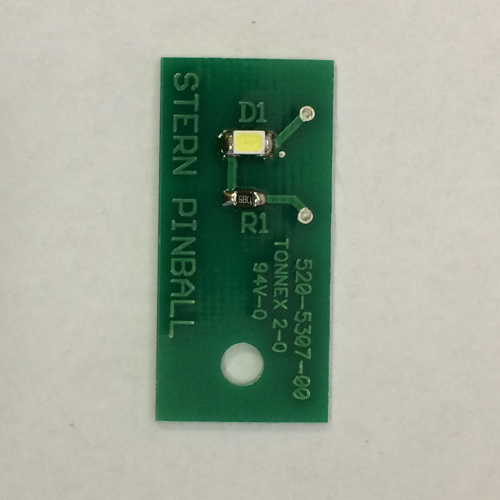

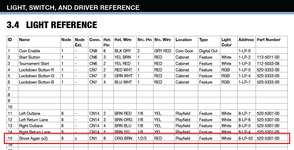

My GZ arrived with the "Again" of "Shoot Again" inserts not lighting up - I tested the light using the Diagnostics menu just to be sure, so then figured I'd need to take a look inside. It would seem this is not as simple as replacing an olde fashioned bayonet bulb so I figured best to check before I break something...!

So the wires seem soldered OK. Presumably I can unscrew this little board, but is the bulb replaceable and if so what do I need to buy and from where please? Or is it integral to the board and non-replaceable (surely not?)?

Also, as I'm scrabbling around using tools that aren't quite right, is there a specific tool people use to remove these? What size nut driver or spanner would this be, or can I just use a screwdriver?

Thanks!

So the wires seem soldered OK. Presumably I can unscrew this little board, but is the bulb replaceable and if so what do I need to buy and from where please? Or is it integral to the board and non-replaceable (surely not?)?

Also, as I'm scrabbling around using tools that aren't quite right, is there a specific tool people use to remove these? What size nut driver or spanner would this be, or can I just use a screwdriver?

Thanks!