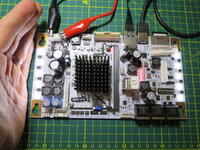

In this thread I will share my adventures repairing broken node boards. There's not a lot of information out there as I guess they don't break that much and/or the people who fix them don't share their findings. Now I'm by no means an electronics super-guru so all comments are very welcome.

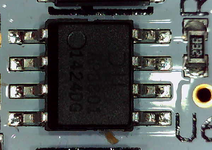

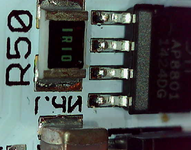

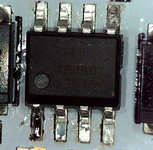

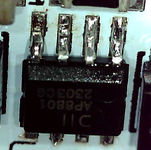

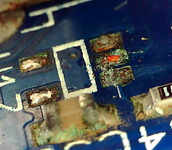

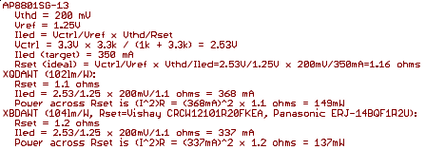

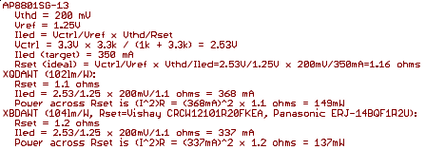

To start with, we have a CPU board on which the backbox LEDs don't work: at startup, they illuminate briefly before cutting out. This board was kindly entrusted to me by @Sam C who has a video of the problem in another thread so check that out if you want. Based on one related pinside thread, it could be the LED driver chip (AP8801SG-13) but I'd like to confirm that before starting shotgun replacements.

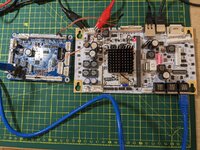

I don't have a spike2 machine in the house however I do have another CPU board which works and will be useful to compare to.

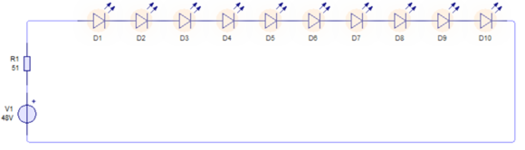

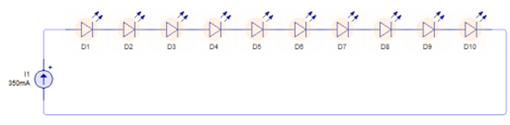

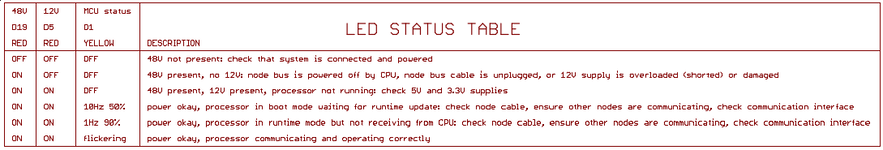

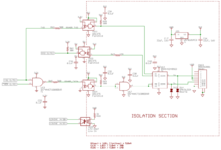

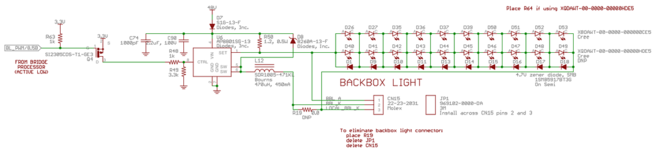

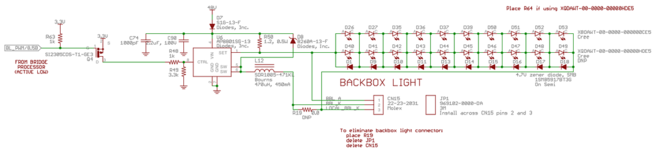

We can get the schematic from Stern's website for this part of the board:

Some interesting points to note:

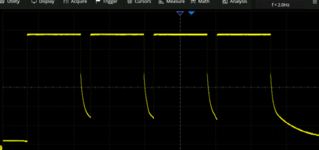

Now since the LEDs do light up briefly we know they all work. The input and output to the chain are easily accessible on CN15 so let's probe that.

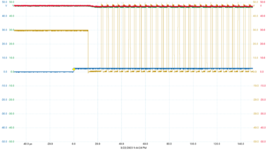

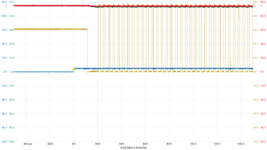

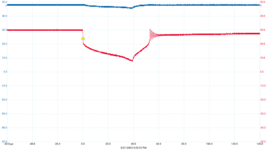

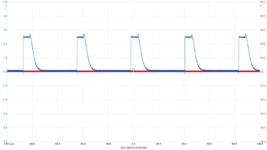

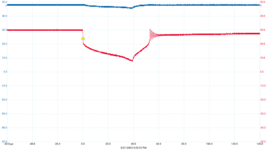

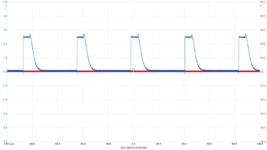

For the keen readers who opened the driver's datasheet, we are effectively probing its SET (blue) and SW (red) outputs (the latter being behind a couple passives). At startup we can see the initial flash:

And afterwards nothing really happens. Let's compare it to our good board...

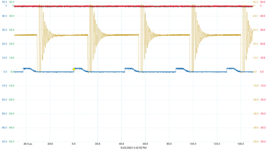

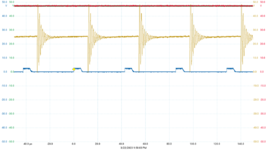

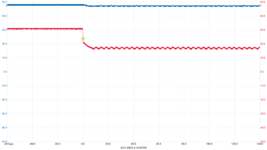

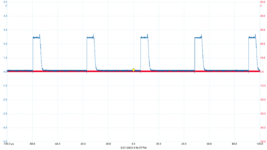

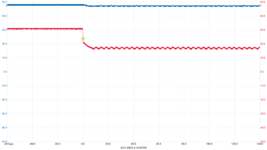

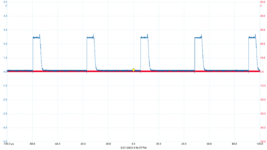

...which eventually reaches this steady state where the LEDs are quite dimmed:

Even non-technical readers at this point will note a marked difference

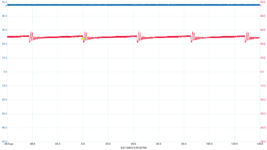

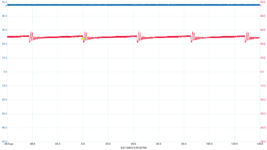

Let's now probe the input (BL_PWM, MCU output) as a sanity check -- note that this board otherwise plays fine so the node bridge processor must be functional -- both test subjects indeed look the same so no need to double the picture:

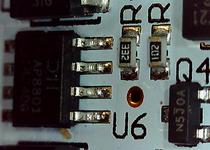

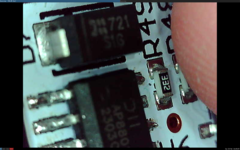

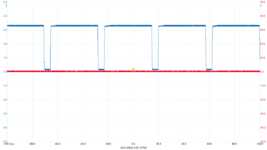

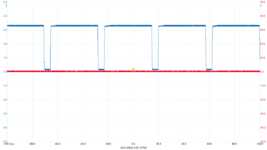

and then after Q4 the inverting MOSFET we have CTRL (driver input), which is slightly different between bad (left) and good (right):

In the BAD case, the falling edge is not as sharp and takes a bit longer to settle. Worth noting that the driver accepts both PWM signals as well as analog voltage variations to control the LED intensity. However I don't see how the above could explain the behaviour we're seeing...

At this point I think it's worth replacing the suspect driver chip, which has conveniently appeared in stock at Farnell. Whilst waiting for that, the next step is to write a little program to manually control the backbox lights, as waiting several minutes for the game to boot each time is proving tiresome. Watch this space!

Whilst waiting for that, the next step is to write a little program to manually control the backbox lights, as waiting several minutes for the game to boot each time is proving tiresome. Watch this space!

To start with, we have a CPU board on which the backbox LEDs don't work: at startup, they illuminate briefly before cutting out. This board was kindly entrusted to me by @Sam C who has a video of the problem in another thread so check that out if you want. Based on one related pinside thread, it could be the LED driver chip (AP8801SG-13) but I'd like to confirm that before starting shotgun replacements.

I don't have a spike2 machine in the house however I do have another CPU board which works and will be useful to compare to.

We can get the schematic from Stern's website for this part of the board:

Some interesting points to note:

- I can't find the top row of LEDs (D26..D53) on the actual board, it looks like they must be an alternative part - or possibly I'm just a bit thick?

- The driving BL_PWM signal comes straight from the node bridge MCU at PIO0_17.

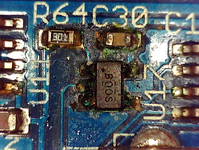

- The comment in the top right mentions R64 but I can't seem to find it??

- The driver chip is running at its max recommended operating voltage (48V), only 2V away from its absolute max rating. Hopefully there are no big spikes on that rail...

Now since the LEDs do light up briefly we know they all work. The input and output to the chain are easily accessible on CN15 so let's probe that.

For the keen readers who opened the driver's datasheet, we are effectively probing its SET (blue) and SW (red) outputs (the latter being behind a couple passives). At startup we can see the initial flash:

And afterwards nothing really happens. Let's compare it to our good board...

...which eventually reaches this steady state where the LEDs are quite dimmed:

Even non-technical readers at this point will note a marked difference

Let's now probe the input (BL_PWM, MCU output) as a sanity check -- note that this board otherwise plays fine so the node bridge processor must be functional -- both test subjects indeed look the same so no need to double the picture:

and then after Q4 the inverting MOSFET we have CTRL (driver input), which is slightly different between bad (left) and good (right):

In the BAD case, the falling edge is not as sharp and takes a bit longer to settle. Worth noting that the driver accepts both PWM signals as well as analog voltage variations to control the LED intensity. However I don't see how the above could explain the behaviour we're seeing...

At this point I think it's worth replacing the suspect driver chip, which has conveniently appeared in stock at Farnell.

Last edited: