I thought that was it in terms of major fun and games but I was wrong! Despite the slam ramp area looking very good, it did have the ramp mark that they all have, I realise there is not much you can do about it but I decided to see what the options were. The most obvious was an overlay decal and in the end I decided to go for it as there are no inserts under the decal so no risk of lifting the insert art (same risk when removing mylar) if I decided it didn't look too good and needed to remove it.

So I made the purchase from a main land Europe supplier and waited for it to arrive, in the mean time the tumber was switched on to do it's polishing duties, all the plastic parts (except ramps!) went in the dish washer and I re-built the pop bumpers

ok, back to the slam ramp area - the decal arrived and in my excitement I didn't carry out a dry run - big mistake as when I fitted the decal I discovered it was too small, argh! Check this out, it is not even close, I had to make the border around the wheel way too thick in order to move the decal up the playfield and it still didn't fit at the top.

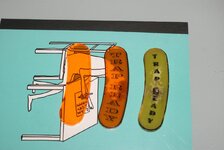

Hopefully you can see what I mean in the image below, from the perspective of the image, note the following:

Centre (ish!) of image - border to thick as I have moved the decal up the playfield the black border is made up of the original playfield black border and the black border of the decal

Right side of image - You can clearly see the original playfield black jagged line, then some red and some yellow of the original playfield followed finally by the black jagged line of the overlay decal - looks horrendous!

bottom of image - The decal is not only too short, it's also too narrow (basically the entire scale is wrong), as a result you can see the playfield yellow followed by the decal black border and then finally the decal yellow so you get an extra yellow stripe on your playfield which you don't want!

As you can guess, that was removed and eventually (after many emails to the seller showing the problem including using rulers and sizing guides!) filed in the bin!

At this point I debated, do I leave it or give it one more go? Well, I already started down this path so went with a company I have always had great products, help and who I trust - treasure cove (there was no one in the uk selling a similar thing, just want to mention it as I am always keen to support our fantastic UK pinball part suppliers). Unfortunately this one was a bit more pricey as it had to be shipped from the USA (I still can't work out why postage from the USA is so expensive - it's much cheaper from Australia for example!), anyway after a week or so I had another overlay. I had already spoken to Treasure Cove and sent them measurements of the previous version as I didn't want to pay for this version if it was the same size (I wondered if there was a problem with the printing on my playfield rather than the decal size but there wasn't and this was confirmed by Treasure Cove).

OK, now we are talking, this overlay is fantastic, not only is the right size but rather than the linear red of the 'other' decal this one had the correct fading, basically it was much better in every aspect, thinner, fits perfect, better colour reproduction! In fact if I didn't tell you it was there you may not even notice!