Hey folks

Hope you're all keeping safe!

I have an issue that i've reached the limit of my diagnosis skills. Stangely, BOTH these issues started at exactly the same time.

Issue 1 : Ball Trough Solenoid

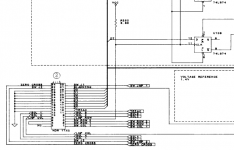

The ball trough solenoid no longer functions. All other solenoids on that circuit work. If i test from the plug J130-1 to the solenoid all is well ~ 0 ohm. I am getting no voltage to the solenoid when in a repeat test. Is there any way to test that the pin on J130-1 is sending the ~50v required?

Issus 2: Lamp Circuit Column 1 is not lighting ANY bulbs on the column. BUT if i power off the machine for a while and power it back on, the Column works for 5 seconds or so before they start to flicker and then stop. If i do a quick reboot, they continue to not work.

Please feel free to ask additional questions to help me narrow down the issue.

Thanks in advance (and hope)

Hope you're all keeping safe!

I have an issue that i've reached the limit of my diagnosis skills. Stangely, BOTH these issues started at exactly the same time.

Issue 1 : Ball Trough Solenoid

The ball trough solenoid no longer functions. All other solenoids on that circuit work. If i test from the plug J130-1 to the solenoid all is well ~ 0 ohm. I am getting no voltage to the solenoid when in a repeat test. Is there any way to test that the pin on J130-1 is sending the ~50v required?

Issus 2: Lamp Circuit Column 1 is not lighting ANY bulbs on the column. BUT if i power off the machine for a while and power it back on, the Column works for 5 seconds or so before they start to flicker and then stop. If i do a quick reboot, they continue to not work.

Please feel free to ask additional questions to help me narrow down the issue.

Thanks in advance (and hope)