Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Easy-out.... or not!!!

- Thread starter Paul

- Start date

This is what I would do, do not take this as professional advice.

Soak in penetration fluid for a while.

Cut in a groove with a dremel

Blow torch it for a while

Chisel in the groove and wack it off center to turn

When that fails, I then drill a small hole with a metal bit.

Then try to use an easy out.

That will fail, never learnt to use them

So then I will find a smaller bolt and try to tack weld it to the broken bolt.

That will cause too much heat and ruin the whole thing.

Then I will use eBay to buy the item again

Soak in penetration fluid for a while.

Cut in a groove with a dremel

Blow torch it for a while

Chisel in the groove and wack it off center to turn

When that fails, I then drill a small hole with a metal bit.

Then try to use an easy out.

That will fail, never learnt to use them

So then I will find a smaller bolt and try to tack weld it to the broken bolt.

That will cause too much heat and ruin the whole thing.

Then I will use eBay to buy the item again

can you get to the thread from the other side?,a pair of mole grips might be able to remove it now the head has come off the bolt.

I was thinking that, however the only way in is to break whatever weld is there and try to go in from the end.....

Other alternative i have thought of - try to fracture the weld where on the bolt "holder" and get that out... nothing obvious as to how it is held on - suspect it may be spot welded... might cause less damage though....

This is what I would do, do not take this as professional advice.

Soak in penetration fluid for a while.

Cut in a groove with a dremel

Blow torch it for a while

Chisel in the groove and wack it off center to turn

Thought of that... Problem is the bolt remover will be carbon steel i suspect, so wether it's drilling through it or cutting a groove, will need to be something stronger... Drill bits just dont touch it...

Get it cherry red with a blowtorch and get a cold chisel ( hardened ) and tap it out following the thread, can go both anti and clockwise till it’s loose, heat is your friend here

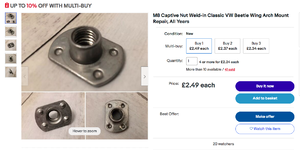

That to me looks like a captive nut like these... I've seen enough of these in my time with VW restoration! I think you'll find it was pushed into the hole from below, then spot welded in.I was thinking that, however the only way in is to break whatever weld is there and try to go in from the end.....

View attachment 179845View attachment 179846

Other alternative i have thought of - try to fracture the weld where on the bolt "holder" and get that out... nothing obvious as to how it is held on - suspect it may be spot welded... might cause less damage though....

Looks like it wants grinding out, getting a replacement like the below one (or similar) then a replacement welding in.

so here's a thought.... From the Extractor information...

I'm thinking i may be able to drill it out using a Tungsten Carbide bit (85HRC) or a cobalt drill ......

Damaged screw extractor set & bolt remover is made from H.S.S 4341#, the hardness of this screw extractor set is 62-63HRC, which is stronger than ordinary steel,

I'm thinking i may be able to drill it out using a Tungsten Carbide bit (85HRC) or a cobalt drill ......

Yep, try the drill first. Smaller one then step up. Don't lean on it too hard or you will break the bit, give it a good pilot then step up the size you're after. Something just inside the thread size. With some luck you'll then be able to just run a tap through it and shift the old bolt thread.

Sometimes you get lucky other times well.... not so much. Good luck either way!

Sometimes you get lucky other times well.... not so much. Good luck either way!

And use drilling fluid to reduce the heat and life of the drill bit. It makes a massive difference when I use it.

View attachment Remove a sheared bolt.mp4

This will get it out.

This will get it out.

Depends if you have the equipment or not but I would say best option would be to weld a nut onto the end of the broken bolt using a mig or arc welder inside the nut part, that way the heat of the welding should help to free it up and then you can use a spanner to turn the nut to get the remains of the bolt left.

Drilling out an easy out is not going to be an easy job.

Drilling out an easy out is not going to be an easy job.

If feels like the first 3 suggestions I made have been discussed. That only leave “acknowledge I ruined it and buying from eBay” left.