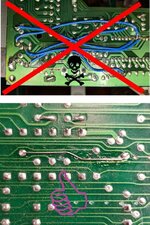

Symptom: when you turn it on, it goes CLUNK CLUNK CLUNK and the filing cabinet goes down and up. You can start the game, but no ball appears.

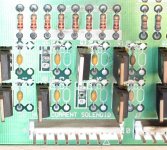

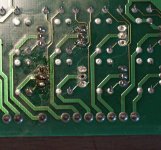

The coil tests seem to do nothing. Flippers work. I've checked DC voltages coming out of all the bridge rectifiers. What's next, the power transistors perhaps or U1 & U2?

Thanks in advance.

The coil tests seem to do nothing. Flippers work. I've checked DC voltages coming out of all the bridge rectifiers. What's next, the power transistors perhaps or U1 & U2?

Thanks in advance.