Hi guys looking for some help with R/H flippers upper and lower on my Mr Mrs Pacman machine

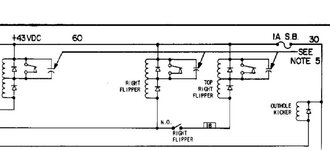

seem to have lost the power stroke to flippers but holding the flipper button in and raising the flippers

manually the hold winding is working, release button and flipper drops. Have checked all larger transistors

on solenoid board and all test ok.

Flipper coils have power so I am guessing something may have gone on the MPU board, looking on pin wiki and clays old guides the operation of the flippers is somewhat lacking in information.

Can anyone on here that can help me as to where to start looking would be greatly appreciated.

thanks in advance John

seem to have lost the power stroke to flippers but holding the flipper button in and raising the flippers

manually the hold winding is working, release button and flipper drops. Have checked all larger transistors

on solenoid board and all test ok.

Flipper coils have power so I am guessing something may have gone on the MPU board, looking on pin wiki and clays old guides the operation of the flippers is somewhat lacking in information.

Can anyone on here that can help me as to where to start looking would be greatly appreciated.

thanks in advance John