Greetings all,

As the title suggests, we are going to be tackling Bally’s 1984 table, Kings of Steel. But first, a tiny foreword about me, if you will allow.

I’ve owned, played, restored and sold arcade machines for a fair few years now, and if anyone is interested, I documented a few of the more prominent restos on a blog which you can find here, Neil's Arcade Diary if you are really desperate for internet content…..

But in recent years, the appeal of owning original cabinets was waning and the lure of the shiny ball was growing ever stronger. I’ve also come to accept that I really enjoy fixing and restoring stuff, more than playing it, and sought a new challenge, a different medium, it seemed all roads led to only one destination….

So, in October 2024 (how time flies…), I picked up my first pinball table, on here, from @Pick Holder . From chatting through the condition, it seemed an ideal opportunity to dip my toe and get to grips with one of these beasts. [not to get sidetracked, but to put your minds at ease, of course I have since acquired more than just this one table..]

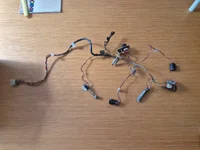

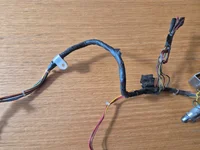

It wasn’t long before Martin had dropped it off and it was in the games room. It was sold as working, but in need of some love. It arrived in two parts with the head unit separate, which led to a few head scratches, fitting the connectors to their corresponding boards, but we got there.

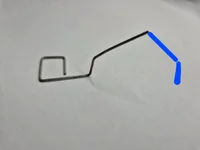

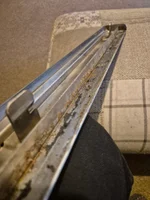

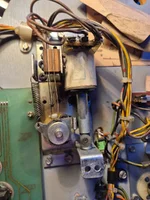

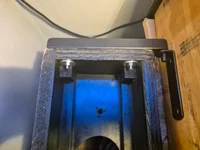

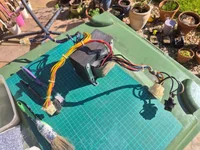

Here’s a few photos of it as it arrived, initial set up and switch on.

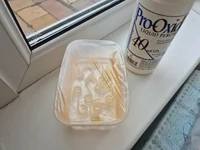

Indeed, it did play. Indeed, it was dirty. It was time to make a list, break out some cleaning products and start to build my knowledge of how these beasts differ from arcade cabs.

One thing to note here, is that I was super excited to get to grips with this new project, no matter what the outcome. Another thing to point out is that I’m not here to make money out of anything I do. I genuinely just love making things look and work better than they did, so if I’m spending on parts that I will never recoup, so be it, leave me alone, I’m in my happy place. Also, I’ll probably make a few mistakes along the way, but that is how we learn, right….

So, here we go, if you want to stick around to see how I get along, then welcome aboard. A lot of the work is already done, with lots of before/after photos ready to post, so I’ll try and keep some regular updates flowing on the thread over the next couple of weeks.

As the title suggests, we are going to be tackling Bally’s 1984 table, Kings of Steel. But first, a tiny foreword about me, if you will allow.

I’ve owned, played, restored and sold arcade machines for a fair few years now, and if anyone is interested, I documented a few of the more prominent restos on a blog which you can find here, Neil's Arcade Diary if you are really desperate for internet content…..

But in recent years, the appeal of owning original cabinets was waning and the lure of the shiny ball was growing ever stronger. I’ve also come to accept that I really enjoy fixing and restoring stuff, more than playing it, and sought a new challenge, a different medium, it seemed all roads led to only one destination….

So, in October 2024 (how time flies…), I picked up my first pinball table, on here, from @Pick Holder . From chatting through the condition, it seemed an ideal opportunity to dip my toe and get to grips with one of these beasts. [not to get sidetracked, but to put your minds at ease, of course I have since acquired more than just this one table..]

It wasn’t long before Martin had dropped it off and it was in the games room. It was sold as working, but in need of some love. It arrived in two parts with the head unit separate, which led to a few head scratches, fitting the connectors to their corresponding boards, but we got there.

Here’s a few photos of it as it arrived, initial set up and switch on.

Indeed, it did play. Indeed, it was dirty. It was time to make a list, break out some cleaning products and start to build my knowledge of how these beasts differ from arcade cabs.

One thing to note here, is that I was super excited to get to grips with this new project, no matter what the outcome. Another thing to point out is that I’m not here to make money out of anything I do. I genuinely just love making things look and work better than they did, so if I’m spending on parts that I will never recoup, so be it, leave me alone, I’m in my happy place. Also, I’ll probably make a few mistakes along the way, but that is how we learn, right….

So, here we go, if you want to stick around to see how I get along, then welcome aboard. A lot of the work is already done, with lots of before/after photos ready to post, so I’ll try and keep some regular updates flowing on the thread over the next couple of weeks.