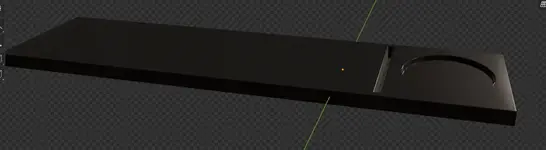

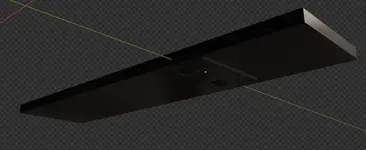

Images below show a coin tester I bought a few years ago. It is precision made and helps to identify fake versus genuine gold coins. There are separate testers for each type of coin.

I want to 3d-print one to test a coin for which I haven't got a tester. The coin weights exactly 1 troy ounce which is 31.1035g The coin is 2.3mm thick and 32.69mm diameter.

The tester is a flat piece of plastic, with a round depression at one end to hold the coin. There are two pivot points on the bottom. A genuine coin will snugly fit in the round depression and will tip the tester over on the pivot points. A lighter, fake coin wont tip it.

The slot in the tester is to test the thickness and width of the coin. Only a genuine coin will fit through. Fakes are either too wide or are too thick, or, if they are the correct dimensions, they will be too light as they are usually made out of

a lighter metal than gold, and then they fail to tip the device on the pivot points. (The only metal that can fool this tester, is fake coins made out of tungsten with a thin 22k or 24k coating - these have been found, but I have a separate solution to that anyway).

I have no idea how to 3d-design this, so looking for someone who can help me please.

I would use JLCPCB to print the final versions using their SLA(resin), Black resin -I looked at the JLCPCB order for something else they 3D printed for me and they said that had 28.04cm-cubed volume which weighs 31.73g so maybe we can calculate the density?

But I think there will be some trial and error to get those pivot points in the right place. It might be worth creating an initial design without them, then use a piece of metal as a temporary pivot to work out exactly where they need to be placed.

Any volunteers please? Beer token or ££ or whatever you need.

I want to 3d-print one to test a coin for which I haven't got a tester. The coin weights exactly 1 troy ounce which is 31.1035g The coin is 2.3mm thick and 32.69mm diameter.

The tester is a flat piece of plastic, with a round depression at one end to hold the coin. There are two pivot points on the bottom. A genuine coin will snugly fit in the round depression and will tip the tester over on the pivot points. A lighter, fake coin wont tip it.

The slot in the tester is to test the thickness and width of the coin. Only a genuine coin will fit through. Fakes are either too wide or are too thick, or, if they are the correct dimensions, they will be too light as they are usually made out of

a lighter metal than gold, and then they fail to tip the device on the pivot points. (The only metal that can fool this tester, is fake coins made out of tungsten with a thin 22k or 24k coating - these have been found, but I have a separate solution to that anyway).

I have no idea how to 3d-design this, so looking for someone who can help me please.

I would use JLCPCB to print the final versions using their SLA(resin), Black resin -I looked at the JLCPCB order for something else they 3D printed for me and they said that had 28.04cm-cubed volume which weighs 31.73g so maybe we can calculate the density?

But I think there will be some trial and error to get those pivot points in the right place. It might be worth creating an initial design without them, then use a piece of metal as a temporary pivot to work out exactly where they need to be placed.

Any volunteers please? Beer token or ££ or whatever you need.