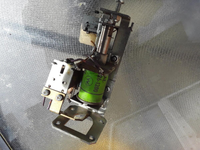

So after pestering everyone on the forum who has a Whirldwind, I finally hit gold when @stumblor agreed to sell me the old beater he had in his possesion. The machine was fully working apart from the lift ramp which didn't move and was pretty much falling off, and the fan in the topper. The right hand upper flipper was also not capable of sending the ball up the ramp opposite.

Other than that, it showed promise. The playfield was a bit beat up and had lifting mylar, worn inserts etc. The cabinet and backbox also looked like someone's XL Bully had taken a few chunks out of it.

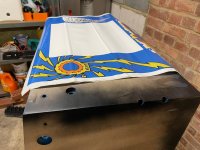

Here's some of the playfield:

Seen worse.

And here's some of the cabinet and backbox with a few of the bites taken out:

Also, there were two extra holes in the front of the cabinet, one with a keyhole in it, and one for no apparent reason

Davey very kindly included ramps, including a new lift ramp, and various other new parts, as part of the deal.

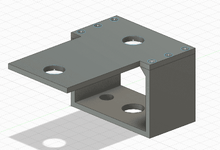

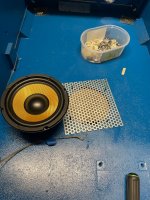

So, the plan is to strip the playfield and install a hardtop, strip and repair the cabinet and backbox, fix any mechs, targets and switches etc and replace if necesary, and then rebuild the pop bumpers and flippers. Then repaint inside the cab and backbox, redecal , reassemble with new ramps and plastics, and replace any other hardware that needs it, like the fan case.

The flippers are currently a mix of Sys 11 and WPC ones, so I will make them all Sys 11 s that they are consistent. And the bumpers will be a bit of a hassle as the game as two sets of three, so six in total. Oh well. Here goes.

Other than that, it showed promise. The playfield was a bit beat up and had lifting mylar, worn inserts etc. The cabinet and backbox also looked like someone's XL Bully had taken a few chunks out of it.

Here's some of the playfield:

Seen worse.

And here's some of the cabinet and backbox with a few of the bites taken out:

Also, there were two extra holes in the front of the cabinet, one with a keyhole in it, and one for no apparent reason

Davey very kindly included ramps, including a new lift ramp, and various other new parts, as part of the deal.

So, the plan is to strip the playfield and install a hardtop, strip and repair the cabinet and backbox, fix any mechs, targets and switches etc and replace if necesary, and then rebuild the pop bumpers and flippers. Then repaint inside the cab and backbox, redecal , reassemble with new ramps and plastics, and replace any other hardware that needs it, like the fan case.

The flippers are currently a mix of Sys 11 and WPC ones, so I will make them all Sys 11 s that they are consistent. And the bumpers will be a bit of a hassle as the game as two sets of three, so six in total. Oh well. Here goes.