Never done a shop log before. Here goes. Bought this yesterday. My grail pin. There was no way on god's earth that I would have bought any other game in this condition. Much more skilled folk than me have done these.

I am not after perfection, or better than new. About as good as new is my target

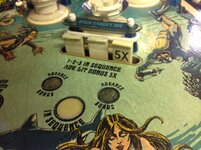

The good news - it is a fathom. I never thought I would actually get to own one. Everything works. Underside of playfield is fine.

The bad news - dog rough. Filthy. Nasty wear to top of playfield that someone foolishly put Mylar on.

Looks encouraging ... Not too bad actually

The oh my god moments .....

Insect graveyard

Lock down bar rust fest

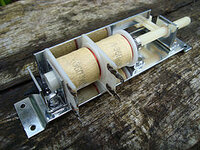

Most solenoid plungers look rusted too

Never thought I would use a wire brush on a power drill on a pinball, but in for a penny ......

I am not after perfection, or better than new. About as good as new is my target

The good news - it is a fathom. I never thought I would actually get to own one. Everything works. Underside of playfield is fine.

The bad news - dog rough. Filthy. Nasty wear to top of playfield that someone foolishly put Mylar on.

Looks encouraging ... Not too bad actually

The oh my god moments .....

Insect graveyard

Lock down bar rust fest

Most solenoid plungers look rusted too

Never thought I would use a wire brush on a power drill on a pinball, but in for a penny ......