There's an adventurer on flea bay for 115. Maybe worth getting cheap to see if 3d printing is for you? (item 225485532011)

Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printers

- Thread starter Wayne J

- Start date

incase you were not aware you can add the AMS to the P1P later if you want color/multi material. And it does actually seem to work reliably unlike prusas efforts.

Also it uses a fork of prusa slicer.

Also it uses a fork of prusa slicer.

It also seems to waste more filament in purging than actually goes in to the model for what I've seen of models printed on YouTube. Also significantly slows down print time, I'd definitely be going work single colour and paintingincase you were not aware you can add the AMS to the P1P later if you want color/multi material. And it does actually seem to work reliably unlike prusas efforts.

Also it uses a fork of prusa slicer.

yeah dosent seem to be any way around that with filament printing. Trade offs like everything. Nice to have the option all the same.

the waste can be cut down allot with settings and by purging through the infill.

Prusa's XL with septate tool heads solves the waste problem to a greater degree but will still be incredibly slow and assuming it works reliably.

The tool change in its self is pretty fast (they quote 20 seconds i think) but Imagine having to heat and prime on every head change. Maybe its smart enough to start heating ahead of each head change??.

Theres always polyjet if you want the best of both. Only 60k for the Stratasys J55 and a mandatory service contract of several grand a year

might be wrong but i think they have a patent on it still so prices for polyjet wont be coming down any time soon!.

Brilliant tech though.

the waste can be cut down allot with settings and by purging through the infill.

Prusa's XL with septate tool heads solves the waste problem to a greater degree but will still be incredibly slow and assuming it works reliably.

The tool change in its self is pretty fast (they quote 20 seconds i think) but Imagine having to heat and prime on every head change. Maybe its smart enough to start heating ahead of each head change??.

Theres always polyjet if you want the best of both. Only 60k for the Stratasys J55 and a mandatory service contract of several grand a year

might be wrong but i think they have a patent on it still so prices for polyjet wont be coming down any time soon!.

Brilliant tech though.

Last edited:

I spiralled again with all the requirements and have gone back and read the advice given here. Amazon are doing the Flashforge Adventurer 3 with £50 off at the moment, so have ordered one. £299 for an easy start printer is not a bad way to learn how it all works.

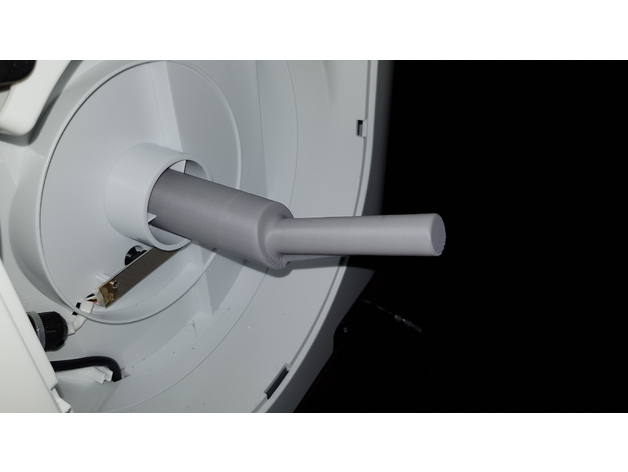

@Wayne J where did you get the larger spool from? I assume this is a self printable option?

@Wayne J where did you get the larger spool from? I assume this is a self printable option?

Just curious - why do you need a larger spool ? Ive printed lots of big things (see the pics in the other thread) and none of them have used more than a 1kg spool ?

The base for dead pool was almost the full bed - 280mmx280mm and was maybe 100 mm high. That was a big part of a spool but not a full one.

The base for dead pool was almost the full bed - 280mmx280mm and was maybe 100 mm high. That was a big part of a spool but not a full one.

It was a recurring theme about this 3d printer that it only could handle a 0.5kg spool and this was annoying as it is more cost efficient to buy 1kg spools. @Wayne J mentioned it in his list of bad points.

As there appears options to print a 1kg spool holder, and then use the 1kg spools, that seems to be a good little early upgrade.

As there appears options to print a 1kg spool holder, and then use the 1kg spools, that seems to be a good little early upgrade.

I spiralled again with all the requirements and have gone back and read the advice given here. Amazon are doing the Flashforge Adventurer 3 with £50 off at the moment, so have ordered one. £299 for an easy start printer is not a bad way to learn how it all works.

@Wayne J where did you get the larger spool from? I assume this is a self

FlashForge Adventurer 3 - Spool Holder by Ronnke

## UPDATED ## Now includes 3 slot and 4 slot version of the holder. External spool holder for the FlashForge Adventurer 3, enabling the use of third party filaments. This holder ensures the spool is held away from the printer housing, so it can spin freely. It's also angled to allow the...

It's a very easy print to get you started

Attachments

Oh.. I've only ever used 1kg ones.

I did print an adapter for the various types of spool but that's not critical

I did print an adapter for the various types of spool but that's not critical

The "problem" with the Flashforge Adventurer is that out of the box it will only take 0.5kg reels, the larger ones don't fit - hence the adaptorOh.. I've only ever used 1kg ones.

I did print an adapter for the various types of spool but that's not critical

I’ve been considering a 3D printer for some time, but thought they were £2k+ to buy.

I want to print high quality board game pieces for fan expansions, and to try to design/build two interactive toppers - for AFM and Alien Poker.

What would people recommend? I’d need toys, and parts, so no complex materials necessary (I don’t think), but I don’t want a rough-looking print.

And, also, what software would I need?

I want to print high quality board game pieces for fan expansions, and to try to design/build two interactive toppers - for AFM and Alien Poker.

What would people recommend? I’d need toys, and parts, so no complex materials necessary (I don’t think), but I don’t want a rough-looking print.

And, also, what software would I need?

"I want to print high quality board game pieces"

you want resin for that really not FDM. Have a few at work, elegoo saturns been rock solid, nice size build volume as well about £350. Also will need a cure unit. Anycubic wash and cure + is great about £200. Or an ultra sonic will do for washing also £40-150ish depending on the size.

Its messy and smelly and you need a reasonable amount of working space to set it all up.

Or just go with fdm and live with the lesser quality for the smaller and/or higher detail things.

I only use fdm for functional/engineering type parts. All figure work and high detail work is resin.

you want resin for that really not FDM. Have a few at work, elegoo saturns been rock solid, nice size build volume as well about £350. Also will need a cure unit. Anycubic wash and cure + is great about £200. Or an ultra sonic will do for washing also £40-150ish depending on the size.

Its messy and smelly and you need a reasonable amount of working space to set it all up.

Or just go with fdm and live with the lesser quality for the smaller and/or higher detail things.

I only use fdm for functional/engineering type parts. All figure work and high detail work is resin.

Im currently resisting the urge to get a resin one to compliment my FDM. Problem is whilst you can get them quite cheap I know I will regret getting one that's reasonably small (especially since my CR10 has a pretty big bed).

So time you get a large-ish one, and the wash/cure station it soon mounts up. (Currently around £800 in fact time you buy some resin).

So time you get a large-ish one, and the wash/cure station it soon mounts up. (Currently around £800 in fact time you buy some resin).

a 10" build plate is a really nice sweet spot for resin prints, ive not really felt the need for bigger. Not really printing the same things in resin as with FDM so dont need as large a build volume.

Your overshooting a bit on the budget, i think you can come in at about £600 for a 10" printer, wash/cure unit and some resin and have a nice hobby setup that's reliable and will do everything you need.

For work the 1st saturn i bought paid for itsself after 3 prints . All its done the last year since is print money. Its running everyday and only had 2 prints failures in that time which were both my fault. Pretty great for the price.

. All its done the last year since is print money. Its running everyday and only had 2 prints failures in that time which were both my fault. Pretty great for the price.

I could of bought a much larger unit, but ive just bought another saturn (saturn2) as like i say the build size is a nice sweet spot. With resin you want to be filling the plate each run as much as possible as the LCD only has maybe 1500-2000 print hours on it before replacement, The larger the build volume the more expensive the screens each time, so something to consider when going large.

Few DLP units starting to pop up now in smaller sizes with a much longer print life (upto 20000 hours), but there only small build volumes.

The professional printer i have here is dlp (asiga), supper accurate parts but again small volume.

For me id rather have several 10" printers than one larger one. Its more economical to run and you have more through put for the same price plus redundancy.

Your overshooting a bit on the budget, i think you can come in at about £600 for a 10" printer, wash/cure unit and some resin and have a nice hobby setup that's reliable and will do everything you need.

For work the 1st saturn i bought paid for itsself after 3 prints

I could of bought a much larger unit, but ive just bought another saturn (saturn2) as like i say the build size is a nice sweet spot. With resin you want to be filling the plate each run as much as possible as the LCD only has maybe 1500-2000 print hours on it before replacement, The larger the build volume the more expensive the screens each time, so something to consider when going large.

Few DLP units starting to pop up now in smaller sizes with a much longer print life (upto 20000 hours), but there only small build volumes.

The professional printer i have here is dlp (asiga), supper accurate parts but again small volume.

For me id rather have several 10" printers than one larger one. Its more economical to run and you have more through put for the same price plus redundancy.

Last edited:

This is an eye-opener because I'd been expecting to pay £2k for a 3D printer...Im currently resisting the urge to get a resin one to compliment my FDM. Problem is whilst you can get them quite cheap I know I will regret getting one that's reasonably small (especially since my CR10 has a pretty big bed).

So time you get a large-ish one, and the wash/cure station it soon mounts up. (Currently around £800 in fact time you buy some resin).

"I want to print high quality board game pieces"

you want resin for that really not FDM. Have a few at work, elegoo saturns been rock solid, nice size build volume as well about £350. Also will need a cure unit. Anycubic wash and cure + is great about £200. Or an ultra sonic will do for washing also £40-150ish depending on the size.

Its messy and smelly and you need a reasonable amount of working space to set it all up.

Or just go with fdm and live with the lesser quality for the smaller and/or higher detail things.

I only use fdm for functional/engineering type parts. All figure work and high detail work is resin.

Thanks! The first thing I wanted to do was this:

"forbidden stars" 3D Models to Print - yeggi

10000+ "forbidden stars" printable 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for forbidden stars Models for your 3D Printer.

i.e. print player pieces for all the fan factions for the board game Forbidden Stars.

Then, I've got a crazy idea in my head for a topper for Alien Poker with a vinyl backplate showing the view out of the spaceship window, and then a 3D model of three aliens sitting around a card table. The idea (and I'd have to spend ages on the electronics and mechs) is that, depending on whether you hit the aces, or knock down the drop targets, one of the three aliens pop out of his/her/its chair (with excitement).

No idea if I could get that to work, or how I'd get it to work, or whether I'd be able to do it without custom metal parts, but it would be very cool. I guess I'd have to hand-paint the aliens (not a problem) as the print resin is mono-coloured...

Last edited:

My first one was £120 on EB. That was awful.This is an eye-opener because I'd been expecting to pay £2k for a 3D printer...

My second was £350 - still got it and it works great. Many of the models in the other thread came from that.

Most recent one was £600 and I dont like it - spangly version of the £350 one twice as expensive and 10x as much bother.

Can get a reasonable sized resin one for 400-600, 200 for the wash and cure deely.

Any recommendation on 1.75mm PLA to buy for the Adventurer 3? The Amazon reviews for everything seem hit and miss, but I expect 0.3kg of the stuff the machine comes with to be exhausted pretty quickly. First print will be the spool holder to go larger than 0.5KG.

I haven't had issues with ANY of the different brands I've purchased from Amazon or eBay, including the budget ones.Any recommendation on 1.75mm PLA to buy for the Adventurer 3? The Amazon reviews for everything seem hit and miss, but I expect 0.3kg of the stuff the machine comes with to be exhausted pretty quickly. First print will be the spool holder to go larger than 0.5KG.

I'd recommend keeping a log of everything you print, as the colours from different brands differ slightly.

You can get test cards from Thingiverse. Or design something yourself as your first project.

I started printing the test cubes with every new filament to check how it printed, and then referencing them againt my orders.

Then i realised i had lost track, so started printing credit card sized pieces with the name and brand of the filament used on and nozzle used.

Before coming to the conclusion that they all print pretty much perfectly

You can get test cards from Thingiverse. Or design something yourself as your first project.

I started printing the test cubes with every new filament to check how it printed, and then referencing them againt my orders.

Then i realised i had lost track, so started printing credit card sized pieces with the name and brand of the filament used on and nozzle used.

Before coming to the conclusion that they all print pretty much perfectly

Flashforge 10745 3D Printer Creator Pro Dual Extruder Printer with Optimized Build Plate and Upgraded Spool Holder https://amzn.eu/d/dsrJ8s9

I've just treated myself for my birthday.

I probably won't use the 2 nozzles much but it does have a slightly bigger build plate at 227 x 148 x 150 mm.

Will report back once it arrives .

I've just treated myself for my birthday.

I probably won't use the 2 nozzles much but it does have a slightly bigger build plate at 227 x 148 x 150 mm.

Will report back once it arrives .

Hot end temperature makes a massive difference to the resultant print. Too hot and you get a lot of stringing. Too cold and you dont get the right flow rate.

Wayne IMO has the right idea - however one other thing to do is to print a temperature tower - this gives you an idea of the best temp for that particular filament.. then write on the spool what to print it at.

www.thingiverse.com

www.thingiverse.com

Wayne IMO has the right idea - however one other thing to do is to print a temperature tower - this gives you an idea of the best temp for that particular filament.. then write on the spool what to print it at.

Temp tower PLA, PETG, ABS by krpavlu

This is a remix of Tempreature tower by Tronnic. I've made a tower for ABS and added small texts to the bases of towers which says in wich filament it was printed with. If you have any questions or suggestions, write them in the comments or message me. I will be happy, if you leave some positive...

"I want to print high quality board game pieces"

you want resin for that really not FDM. Have a few at work, elegoo saturns been rock solid, nice size build volume as well about £350. Also will need a cure unit. Anycubic wash and cure + is great about £200. Or an ultra sonic will do for washing also £40-150ish depending on the size.

Its messy and smelly and you need a reasonable amount of working space to set it all up.

Yes, good advice, I got the Saturn 2 8K = £450 because I will be remaking toys / figures and I don't want any visible layers, most of it will be covered in paint anyway but still you can see it in the filament models.

Those wash & cure stations do take a lot of the mess and hassle away, that thing was a godsend really. As you can see it takes up just part of my table with space to work on in the front.

I made the cover over the weekend and left the resin in the tank open and first time I've seen that dry up, so cleaning that can be bit of hassle but it doesn't take that long.

Printing at 0.1 mm reduces it a lot though. Primer filler helps too. (you still need some post process however if you want to get rid altogether)

Course printing at 0.1 takes even longer

Does the cover on the resin printers mean you don't need to worry about fumes as such. I'm still trying to talk myself out of splurging on a resin on - needing to install an extraction fan in my shed would help me do that

Course printing at 0.1 takes even longer

Does the cover on the resin printers mean you don't need to worry about fumes as such. I'm still trying to talk myself out of splurging on a resin on - needing to install an extraction fan in my shed would help me do that

Printing at 0.1 mm reduces it a lot though. Primer filler helps too. (you still need some post process however if you want to get rid altogether)

Course printing at 0.1 takes even longer

Does the cover on the resin printers mean you don't need to worry about fumes as such. I'm still trying to talk myself out of splurging on a resin on - needing to install an extraction fan in my shed would help me do that

The lowest I've done is 0.01mm which does take longer but I would only use that on a final print.

The hood is good in the sun as it is, but the cover is just to keep the light off it because it's right in the window there as well. That's just so you have to keep emptying it, if you keep in dark then the resin can just sit in the tank and it can be used when you want to.

I haven't had any resins that really smell yet but it is fitted with a carbon filter I have highlighted which only runs when printing.

no it wont get rid of the fumes. Elegoo sell ittle usb carbon filters you can put inside the lid (saturn 8k/2 comes with one in the box) they help a bit but not great.

The saturn 2 already has a hole drilled for a bit of flexible ducting so you can vent outside if breathing in VOC's all day bothers you

Dont forget about how to dispose of the the toxic wast IPA once its spent and i know a number of people now with contact dermatitis from handling the resins regularly without gloves.

Other than that its great

The saturn 2 already has a hole drilled for a bit of flexible ducting so you can vent outside if breathing in VOC's all day bothers you

Dont forget about how to dispose of the the toxic wast IPA once its spent and i know a number of people now with contact dermatitis from handling the resins regularly without gloves.

Other than that its great

Double post

So if it was in my shed and I had charcoal filter I wouldn't need an extractor. Not helping

I'm mean I was thinking of picking up a used cooker hood fan to put in there for when I spray my models...

Was looking at the any cubic m3 plus - I know if I get a small one I will wish I had gone larger.

I'm mean I was thinking of picking up a used cooker hood fan to put in there for when I spray my models...

Was looking at the any cubic m3 plus - I know if I get a small one I will wish I had gone larger.