Just my luck - get a shiny new toy and it breaks down after only a few days

So last night I was playing CV and suddenly I notice smoke coming out of the right slingshot. That's some really neat theme integration I says to myself before hastily cutting the game's power. At this point I didn't notice if the sling's arm was stuck in the "out" position, but I guess it may have been.

The slingshot bracket was quite warm, and the coil very hot. No signs of frayed wires or other nasties. Took the coil out and there was a small amount of liquid goop on the stop which I assume is due to the sleeve melting.

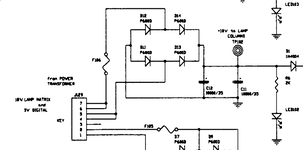

Unsolder the coil, check with ohm meter and it reads 0.5 ohms - not good. Turn the game back on, things are fine except a bunch of solenoids don't work (other sling, pops, trough eject, saucers). Quickly traced down to a blown fuse (couldn't it have blown sooner? Grrrr!) Of course I only have standard fuses and not the 20mm WPC ones...

So this is my shopping list so far:

Any advice gratefully received - this is my first WPC game so not super familiar with their electronics Thanks

Thanks

So last night I was playing CV and suddenly I notice smoke coming out of the right slingshot. That's some really neat theme integration I says to myself before hastily cutting the game's power. At this point I didn't notice if the sling's arm was stuck in the "out" position, but I guess it may have been.

The slingshot bracket was quite warm, and the coil very hot. No signs of frayed wires or other nasties. Took the coil out and there was a small amount of liquid goop on the stop which I assume is due to the sleeve melting.

Unsolder the coil, check with ohm meter and it reads 0.5 ohms - not good. Turn the game back on, things are fine except a bunch of solenoids don't work (other sling, pops, trough eject, saucers). Quickly traced down to a blown fuse (couldn't it have blown sooner? Grrrr!) Of course I only have standard fuses and not the 20mm WPC ones...

So this is my shopping list so far:

- New coil & sleeve

- Fuses (lots) going to check all for correct ratings

- New TIP102

Any advice gratefully received - this is my first WPC game so not super familiar with their electronics

Last edited: