Thought it might be interesting, and hopefully useful, to keep a log of my findings as I attempt to fix a big pile of old solid-state Bally boards.

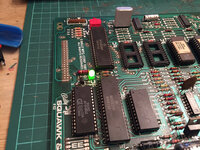

Here's what I started with:

Right at the back are 6 x AS-2518-35 MPU MODULE boards.

Front-right is a pile of 3 x AS-2518-22 SOLENOID DRIVER / VOLTAGE REGULATOR boards.

Front-middle is a stack of 4 x AS-2518-23 LAMP DRIVER MODULE boards.

Sat on top of those is a Rottendog replacement for an AS-2518-18 RECTIFIER BOARD ASSEMBLY.

Just behind that is an AS-2518-52 AUXILIARY LAMP DRIVER board.

In the lower-left is an AS-2518-50 SOUND MODULE from, I think, a PARAGON.

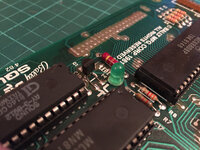

The modern bright green board behind that is an ALLTEK ULTIMATE LAMP DRIVER BOARD.

And at the back upper-right is a WILLIAMS 1B-2001-131-2 DRIVER BOARD for System 3-7 machines.

Finally, there was also a BALLY MPU CORROSION REPAIR KIT (not pictured).

I'm very pleased with that little lot! The Rottendog rectifier is a drop-in replacement for my PARAGON, so that's a keeper. The sound board will be handy too if it's from a PARAGON because mine occasionally makes a few duff noises. The aux lamp driver is used in VECTOR, so handy to have a spare.

The Alltek lamp driver is a very pleasant surprise. On initial inspection I can't see anything wrong with it other than a few connector pins that got bent during transit. It's so modern I can't believe it's failed already. Also, Alltek offer a lifetime warranty as long as " it doesn't look like it has been run over by a truck." I wanted to try converting my VECTOR to LEDs so it's ideal as it solves all the LED flicker problems with any modifications to the rest of the machine.

Here's what I started with:

Right at the back are 6 x AS-2518-35 MPU MODULE boards.

Front-right is a pile of 3 x AS-2518-22 SOLENOID DRIVER / VOLTAGE REGULATOR boards.

Front-middle is a stack of 4 x AS-2518-23 LAMP DRIVER MODULE boards.

Sat on top of those is a Rottendog replacement for an AS-2518-18 RECTIFIER BOARD ASSEMBLY.

Just behind that is an AS-2518-52 AUXILIARY LAMP DRIVER board.

In the lower-left is an AS-2518-50 SOUND MODULE from, I think, a PARAGON.

The modern bright green board behind that is an ALLTEK ULTIMATE LAMP DRIVER BOARD.

And at the back upper-right is a WILLIAMS 1B-2001-131-2 DRIVER BOARD for System 3-7 machines.

Finally, there was also a BALLY MPU CORROSION REPAIR KIT (not pictured).

I'm very pleased with that little lot! The Rottendog rectifier is a drop-in replacement for my PARAGON, so that's a keeper. The sound board will be handy too if it's from a PARAGON because mine occasionally makes a few duff noises. The aux lamp driver is used in VECTOR, so handy to have a spare.

The Alltek lamp driver is a very pleasant surprise. On initial inspection I can't see anything wrong with it other than a few connector pins that got bent during transit. It's so modern I can't believe it's failed already. Also, Alltek offer a lifetime warranty as long as " it doesn't look like it has been run over by a truck." I wanted to try converting my VECTOR to LEDs so it's ideal as it solves all the LED flicker problems with any modifications to the rest of the machine.

.

.