I recently had my garage roof done, just in bloody felt again, but probably gonna change it next year cos the guys who did it did a crap job.

What stopped me from going with EPDM was when I looked into it the rubber membrane seemed quite thin. I was concerned about birds pecking at it (lots of em round here).

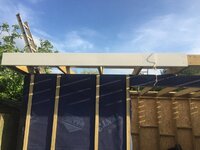

But, looking at your video above that membrane looks decently thick. Found this kit on eBay which will cover my 3.2m x 8m pin shack for £487:

http://www.ebay.co.uk/itm/EPDM-Rubb...hash=item41ad07f4a2:m:mNhVcsuAAbsienbW7iXSoIQ

What do you think Kev, decent? Where did you buy your kit?

Just found this which is also very interesting Pete - Rubber Vs Felt .....

Rubber Vs Felt

RUBBER vs FELT

The truth behind what some roofers will say to get the job

With todays economic downturn its at no suprise that many people fabricate a situation to achieve a sale. Money is scarce and for those who have families to support will try and sell their services at any costs to get a sale, this however can go too far when they feel the only way they can better their product against something more superior is to (lets say) embelish the truth for their benefit to aquire a sale. By doing this, the customer is in no means to question the words of the professional and will therefore believe these embellished words unless they have personally took the time out to research the product themselves. This article I am writing is paying particular attention towards some of the stigma towards rubber roofs and what some (not all!) felt roofers like to say in reguards of the EPDM materials used. Below are some examples which I have found:

“

If someone tries to clamber/climb onto your flat roof, and dig their nails into the rubber they will pierce it”

This is impossible due to the composition of rubber and it being adhered to a hard surface underneath- I would be more than happy to challenge anyone with the strongest nails to try and claw their way through a piece of EPDM! This also applies to any animal including cats and bird tallons.

“

The rubber which is used is too thin”

This is nonsence, EPDM is such a superior product it does not need to be thicker than 1.52mm at most again due to rubber composition and no joins.

“

Over time, the rubber will bubble and blister, it won't last!”

A correctly installed EPDM roof has been scientifically proven to last up to 50 years. Chicago Airport's EPDM roof that was installed in the 60's is still going strong to this day! If EPDM is such a poor product as some people say- then how come so many big branded companies such as Firestone, a renouned tyre manufacturing giant, use this product and promote its abilities using their brand and logo.

Now there's no easy way to say this- but the fact of the matter is that felt roofs will nearly allways be cheaper than the EPDM installation, but by choosing the “cheaper option” of felt you will never aquire the superiorism rubber roofs achieve when installed. A good felt roof installation will only last you at most 10-15 years compared to the 50 year lifespan of rubber, therefore costing you much more money in the long run.

With Britain's climate recently becoming more erratic around our summer and winter months, the effect it is having upon felt flat roofs is devastating resulting in cracks within the asphalt, the weather will have no impact upon an EPDM roof as rubber can expand and contract when needed.

Cracks can also appear upon a felt flat roof if there is any subsidence within the building, rubber allways remains flexible and would therefore “move” with the subsidence.

On your average flat roof, EPDM rubber will have no joins decreasing any opportunity for leakage compared to a matrix of joins used in felt installation. Not only this but with no joins, EPDM looks incredibly pleasing to the eye, and when correctly installed looks very smart and attractive for your house or work premises, something (I believe) felt just doesn't quite do!

I hope this has helped clear up any taboo topics reguarding EPDM rubber roofs. With the “dog eat dog” attitude in any business industry nowadays, it is allways important to keep the facts straight and true for the customer to decide rightfully.