19-October-2016

TESTING TRANSFORMER & AS-2518-54 PSU MODULE

Ok, time to start working out what's wrong with this sucker. No electrical system is going to work unless you have a solid power supply. First things first, fresh batteries in my Precision Gold WG020 Multimeter. Got this cheap as chips from Maplin. It's got a big display, grippy rubber case to take the inevitable knocks and drops, and measure Volts up to 1,000 DC and 750 AC. It also does Impedance, Frequency, Duty, Resistance, Capacitance, NPN/PNP transistor testing and current up to 10A. Decided to treat it to a quality battery

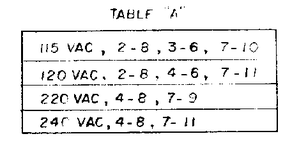

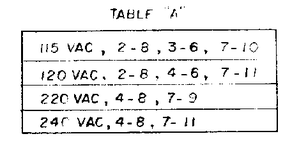

Next I double-checked that the INPUT voltage selector jumpers were correct for 240 VAC in the UK. This is done by setting either 2 or 3 jumper wires between various points in the

J1 connector that is mounted on the main PSU panel in the bottom of the cabinet. This is also where the F1 3A Slow Blow fuse is mounted (checked that too!) and is fed by the pair of wires from the ON/OFF switch on the underside of the cabinet. For UK 240 VAC two jumpers between pins 4-8 and 7-11 have to be set, which they were:

First tests are to make sure the transformer is kicking out the correct supply voltages. Pinball machines have multi-tapped windings on both the input and output, meaning that they can be configured for the different supply voltages around the world and generate a set selection of different output voltages. To check the outputs remove connectors

J5 and

J6 from the AS-2518-54 module. Then poke your test leads into the appropriate holes in the connectors.

!!! PLEASE REMEMBER YOU ARE DEALING WITH LIVE MAINS ELECTRICITY !!!

!!! IF YOU DON'T KNOW WHAT YOU ARE DOING YOU CAN DIE !!!

!!! IF YOU DO KNOW WHAT YOU ARE DOING YOU CAN STILL DIE !!!

!!! PLEASE TAKE APPROPRIATE PRECAUTIONS - EITHER DISCONNECT THE MAINS BETWEEN EACH TEST OR USE HEAVY DUTY GLOVES !!!

Right, appropriately large safety message posted. You have been warned. I like to wear gloves

and switch off and disconnect the mains. It's time consuming but so much better than being electrocuted. Here are the results:

J5 Pin 1 or 4 YELLOW and Pin 7 or 8 YELLOW/BLACK 6.5 VAC

Test reading: 6.5 VAC

J5 Pin 2 RED and Pin 3 RED 170 VAC

Test reading: 179.3 VAC

J5 Pin 2 RED and Pin 3 RED 170 VAC

Test reading: 179.3 VAC

J5 Pin 2 GREEN and Pin 3 ORANGE 49 VAC

Test reading: 49.5 VAC

J5 Pin 2 GREEN and Pin 3 ORANGE 49 VAC

Test reading: 49.5 VAC

J6 Pin 2 PURPLE and Pin 3 PURPLE/BLACK 9.4 VAC

Test reading: 9.5 VAC

J6 Pin 2 PURPLE and Pin 3 PURPLE/BLACK 9.4 VAC

Test reading: 9.5 VAC

J6 Pin 2 BLUE and Pin 3 BLUE 14.2 VAC

Test reading: 14.0 VAC

J6 Pin 2 BLUE and Pin 3 BLUE 14.2 VAC

Test reading: 14.0 VAC

All of these readings are well within tolerance. You don't expect

exactly the same values as the schematic. Transformers have a little natural variance. Also, the output voltages can be a little different when not under load, just like during this test as everything is disconnected. Basically what I've established here is that the transformer looks good and isn't total toast. Doesn't prove it's perfect as it could still go wonky under load but we're off to a good start!

Next, it's time to test the performance of the

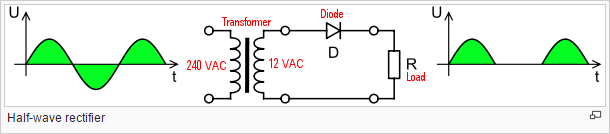

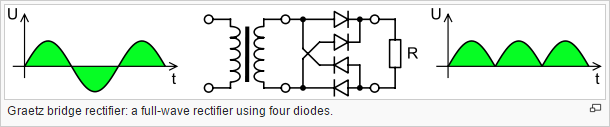

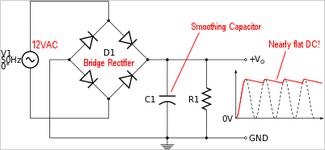

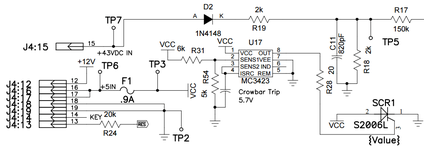

AS-2518-54 rectifier module. This board is very simple and is basically 5 separate circuits in one board with fuses with AC to DC rectification on 4 circuits. GI or General Illumination is run on 6.5 VAC so no rectifier is needed.

During testing the output connectors

J1,

J2,

J3 and

J4 are removed - we don't want any faults or shorts further down the line interfering. Alligator clips were then added to the test probes so that they can be easily clipped onto the test points (TP).

TP1 6.5 VDC SW.IL. (SWITCHED ILLUMINATION)

Test reading: 7.36 VDC

TP2 +230 VDC (UNREGULATED 190)

Test reading: 173 VDC

TP2 +230 VDC (UNREGULATED 190)

Test reading: 173 VDC

TP3 11.9 VDC (UNREGULATED +5V)

Test reading: 34.2 VDC using GND

TP3 11.9 VDC (UNREGULATED +5V)

Test reading: 34.2 VDC using GND

Test reading: 11.3 VDC using base of CR6

Test reading: 11.3 VDC using base of CR6

TP4 6.5 VAC GI (GENERAL ILLUMINATION)

Test reading: 6.5 VAC

TP4 6.5 VAC GI (GENERAL ILLUMINATION)

Test reading: 6.5 VAC

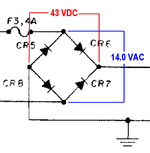

TP5 +43 VDC (SOLENOIDS)

Test reading: 43.4 VAC

TP5 +43 VDC (SOLENOIDS)

Test reading: 43.4 VAC

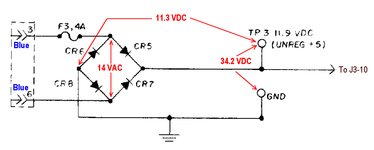

Those of you still paying attention and not scrolling past all the seemingly identical photos will have noticed that I've got a dodgy reading on TP3. I should be getting 11.9 VDC but it's reading just over 34 VDC! But the really strange thing is after testing the input and output voltages on the bridge rectifier formed by diodes CR5, CR6, CR7 and CR8 I noticed that the output measured at TP3 was 11.3 VDC if I used the base of CR6 as the ground point. This is weird because the base of CR6 should be connected to the GND test point on the board!

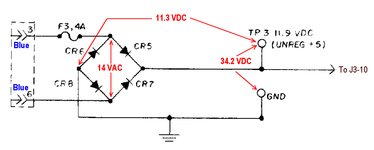

Here's the relevant part of the schematic showing where the voltages were measured:

We know that 14.0 VAC is on the blue wires from J6 and I measured that directly across the BR (Bridge Rectifier) formed by diodes CR5/6/7/8. I also checked the output of the BR directly by clipping probes onto the base of CR6 and head of CR7. And as tested earlier there's 11.3 VDC between the base of CR6 and TP3. But when I move the black probe from CR6 to the GND test point I get 34.2 VDC. There's a leak somewhere!

Next task will be to remove the board from the chassis and inspect it for and shorts, e.g., bits of solder. Have to admit at this stage I'm a bit flummoxed