When I had my Gorgar the first time I powered it up ,I had to have the coin door open to get it in attract mode ,then after that it was fine ,was told later it was because we took the head off to transport it !

That wasn't right, it would've been due to the Cmos ram being corrupt, probably from battery problems. How were you supposed to transport it, anyway, when it didn't have a hinged backbox?

The caper with the door having to be open to boot in attract mode in this situation is what's lost by putting an L6 program on an L4 board - when closed, the switch prevents factory settings being installed

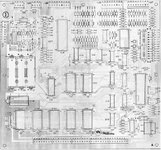

I'd have to check with the slightly risible Williams troubleshooting book (which assumes spare boards grew on trees), but I don't think the Cpu board will boot fully on its own, without the driver board attached. The PIA chips on the driver board are part of the Cpu architecture, AIR

I looked at this games' entry on the database ipdb.org yesterday, and saw a bulletin which mentioned the original-fitment Cpu for Laser Ball, Firepower and King Tut (a 'shuffle' game using this hardware) having two of the smaller 'transceiver' 8T28 chips replaced by simple pad-to-pad links

Last edited: