Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Complete Demolished Man!! - A painful and very slow shop log!

- Thread starter newdos

- Start date

-

- Tags

- demolition man

And here it is done stood next to the upper flipper mech which is next

Pulled this mech to bits and soon found out why the hold didnt work on the flipper!!! see the snapped coil wire

Now fixed and this mech also complete!!!

All 3 flipper mechs done

![IMG_1033[1].JPG IMG_1033[1].JPG](https://www.pinballinfo.com/community/data/attachments/26/26268-1a70ec0988fbf678f84ba73e723fd7b0.jpg)

Onto a couple of opto mounts next and the shooter mech

Very badly rusted and pitted so not sure how these will do

shooter mech before

Cheers Kev

Pulled this mech to bits and soon found out why the hold didnt work on the flipper!!! see the snapped coil wire

Now fixed and this mech also complete!!!

All 3 flipper mechs done

![IMG_1033[1].JPG IMG_1033[1].JPG](https://www.pinballinfo.com/community/data/attachments/26/26268-1a70ec0988fbf678f84ba73e723fd7b0.jpg)

Onto a couple of opto mounts next and the shooter mech

Very badly rusted and pitted so not sure how these will do

shooter mech before

Cheers Kev

Attachments

I love you, Kev!

More progress on de rusting and plating!!

Those really badly rusted optos done - not brill but better

Also did the top divertor yesterday - from this.......

to this!!!

Next fro the treatment was the ball popper - quite a big mech to do

Before - wasnt to bad

and after.......

Thats all for yesterday on with the ball trough today gonna be fun this one as its a large part and very awkward to clean

here are a couple of befores......

Will show you the results later

Cheers Kev

Those really badly rusted optos done - not brill but better

Also did the top divertor yesterday - from this.......

to this!!!

Next fro the treatment was the ball popper - quite a big mech to do

Before - wasnt to bad

and after.......

Thats all for yesterday on with the ball trough today gonna be fun this one as its a large part and very awkward to clean

here are a couple of befores......

Will show you the results later

Cheers Kev

OK here it is finished today - not bad compared to how it was above!

Next job was to tackle this beast, but as you can see it is held together with sticky tape and tie wraps!!

So all I have done for today is take it apart - well it fell apart, and then clean it up ready to go to the welders

That's it for today folks!!!

Cheers Kev

Next job was to tackle this beast, but as you can see it is held together with sticky tape and tie wraps!!

So all I have done for today is take it apart - well it fell apart, and then clean it up ready to go to the welders

That's it for today folks!!!

Cheers Kev

Can't believe the amount of love you're giving this. Amazing!

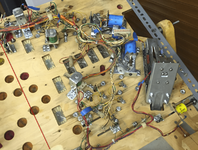

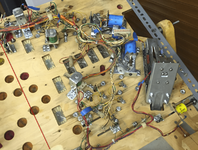

Refitted a lot of the mechs to the playfield today (put all the coils on the flippers the right way around as well as I always fitt them back to front DOH!) - so in this pic you can now see how much of the playfield is complete - about 1/3rd !! long way to go. The red line is about where I am up to

And here is the closest before I could find for comparison !!!

Cheers Kev

And here is the closest before I could find for comparison !!!

Cheers Kev

Last edited:

Bit of soldering tomoz me thinks, then move on up the playfiel - more lampholders to replace and switch plates to de-rust and zinc plate!

All this metalwork that you turn from rusty to shiny, that's your acid bath followed by your home zinc plate bath? It's seriously impressive, does it have a cost, a price in renewable ingredients etc?

From what I've read before you get an even better finish if u blast it on a polishing wheel before plating. Like the pitting on the opto plate blast on the scotchbrite wheel then a quick Polish ud get a well good finish with your playing. Still awesome results your getting might do it myself on my next project

Hi Rudi - all the metal work has been seriously blasted on the grinder with a poly wheel on but the pitting is so deep it would have to be filled - ie copper plate it first then flow solder into it then zinc it but that is way to time consuming and costly!!!From what I've read before you get an even better finish if u blast it on a polishing wheel before plating. Like the pitting on the opto plate blast on the scotchbrite wheel then a quick Polish ud get a well good finish with your playing. Still awesome results your getting might do it myself on my next project

Cheers Kev

Thanks Dan - the chemicals in the kit have done everything so far and will do a hell of a lot more then there's enough chemicals with the kit to make another complete set so guess it will last for a good while. It claims it will plate 34000 sq cms !!!All this metalwork that you turn from rusty to shiny, that's your acid bath followed by your home zinc plate bath? It's seriously impressive, does it have a cost, a price in renewable ingredients etc?

Cheers Kev

Hi Rudi - all the metal work has been seriously blasted on the grinder with a poly wheel on but the pitting is so deep it would have to be filled - ie copper plate it first then flow solder into it then zinc it but that is way to time consuming and costly!!!

Cheers Kev

Oh right I didn't realise I thought u had just acid dipped em

Nah mate serious buffed on the poly wheel quickest way to get rust off then acid dipped before plating. Results on good metal is fantastic!!!Oh right I didn't realise I thought u had just acid dipped em

Kev, what does the kit need in terms of ventilaition and how long do you leave things in the various stages? I don't have a garage so would have to do this in the kitchen....just wondering if that's safe if there are fumes etc

fumes aren't bad at all just keep a window open and away from naked flames as you do get a bit of hydrogen emitted. I put it in the degreaser for 5 mins in the acid pickle until it stops bubbling then in the plating bath which varies from a couple of mins to an hour dependent on the size or numbers of bits you are doing at once. Then it goes into a weak HNO3(Nitric acid) bath for 10 secs and finally in the passivate for 30 secs (be it blue or yellow passivate).Kev, what does the kit need in terms of ventilaition and how long do you leave things in the various stages? I don't have a garage so would have to do this in the kitchen....just wondering if that's safe if there are fumes etc

Trick is the voltage flowing through the electrolyte - 1.2v DC seems to best, higher for big parts say 1.5, and lower for small parts 1.0, and that is measured by putting you pos probe into the electrolyte solution and the neg on your negative 12v supply terminal.

It's all in the instructions with the kit

Shout if you need any help - might try and do a video on a small part if anyone wants to see it from start to end result.

Cheers Kev

Think I'll be bookmarking the link

deinitely want to see the video Kev - include the buffing bit as well if you can

It's all in the instructions with the kit

Shout if you need any help - might try and do a video on a small part if anyone wants to see it from start to end result.

I'd love to see that, as well as know which kit you got, and from where. I've got a few machines here w/some rusty fixtures on them that could use a plating like that.

Your results look AWESOME. /me is totally jealous

Here is a link to the kit from earlier in the threadI'd love to see that, as well as know which kit you got, and from where. I've got a few machines here w/some rusty fixtures on them that could use a plating like that.

Your results look AWESOME. /me is totally jealous

http://www.ebay.co.uk/itm/281868008224?_trksid=p2057872.m2749.l2649&ssPageName=STRK:MEBIDX:IT

Cheers Kev

Will do one next time I do some plating then dan and show you how it is all done. Should be sometime next week.deinitely want to see the video Kev - include the buffing bit as well if you can

Cheers Kev

Loving what your doing on this so far Kev quality work ..

id also like to see that metal witchcraft your doing. I'm even thinking about buying the kit and i haven't even got a project pin to use it on

But in all fairness i know for SURE i don't want to watch you buffing your thing first.. Jesus !!

id also like to see that metal witchcraft your doing. I'm even thinking about buying the kit and i haven't even got a project pin to use it on

But in all fairness i know for SURE i don't want to watch you buffing your thing first.. Jesus !!

hahaha!!!!! watch this space!!!Loving what your doing on this so far Kev quality work ..

id also like to see that metal witchcraft your doing. I'm even thinking about buying the kit and i haven't even got a project pin to use it on

But in all fairness i know for SURE i don't want to watch you buffing your thing first.. Jesus !!

Cheers Kev

Howdy Kev.Hi Rudi - all the metal work has been seriously blasted on the grinder with a poly wheel on but the pitting is so deep it would have to be filled - ie copper plate it first then flow solder into it then zinc it but that is way to time consuming and costly!!!

Cheers Kev

What would they come out like if they were shotblasted ? Do you think it would be a better finish than using the poly wheel ?

The shotblaster at work is about the only thing that survived the Christmas flood and I like the look of the stuff that you have plated.

Hi andrew,Howdy Kev.

What would they come out like if they were shotblasted ? Do you think it would be a better finish than using the poly wheel ?

The shotblaster at work is about the only thing that survived the Christmas flood and I like the look of the stuff that you have plated.

I got some stuff shot blasted, it removed the rust and the general surface is very smooth and will plate fantastic - only problem is, even shot blasting will not remove the pitting, unless you use a much coarser material than sand, and then I guess you will have to take away a lot of the surface to get to that level

Cheers Kev

Hi, Kev,

The coil for the upper flipper is missing a diode as well, though it's not essential on the Fliptronic II system (Getaway & later).

The coil for the upper flipper is missing a diode as well, though it's not essential on the Fliptronic II system (Getaway & later).

Yeah I noticed that and thought it was odd that it only had one on - so guess it it came out of factory like that ??Hi, Kev,

The coil for the upper flipper is missing a diode as well, though it's not essential on the Fliptronic II system (Getaway & later).

Cheers Kev

Yeah I noticed that and thought it was odd that it only had one on - so guess it it came out of factory like that ??

Cheers Kev

Nope, you can see the remains of the broken diode leg.

Better eyes than me man I will stick one on just to be sure

Cheers Kev

Cheers Kev